Mailong is a manufacturer specializing in the customized production of toggle clamps. We have professional design engineers and mold engineers. If you have any custom related questions, please contact us:

Product customization is our forte

come see how we work

Customized products can solve the actual problems of customers to the greatest extent. Mailong is good at customizing products for customers. Product customization mainly includes the following steps:

Make your request for the product

Understanding and evaluating your ideas and needs is our focus. Our engineering and design team will help you understand what is needed to get your idea made into reality. while providing guidance in the process.

Your ideas and needs are not clear yet? No problem! Just express it. That’s enough to get us started, we pride ourselves on making this process simple and easy.

Design & Engineering Strategy

Discuss ideas and provide examples of previously relevant work that will help you further understand what makes sense for you.

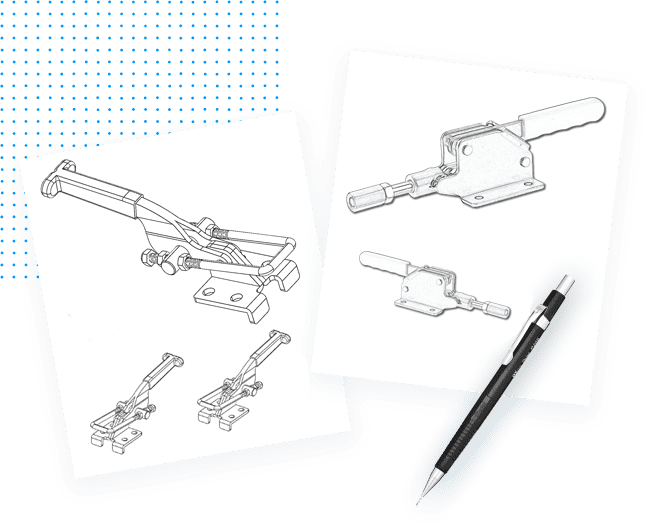

Concept Development & Design

Create sketches and conceptual drawings to achieve the functionality as well as the final look and feel of your custom vertical toggle clamps, horizontal toggle clamps, push-pull clamps, latch type clamps, pneumatic toggle clamps, or anything else you want.

Provide a formal design proposal

Combining engineering and manufacturing is what we’ve spent years perfecting to deliver amazing results in the fastest possible time-frames.

Our designers and engineers will create renderings, concepts, and actual samples for you to help decide on the direction of your project.

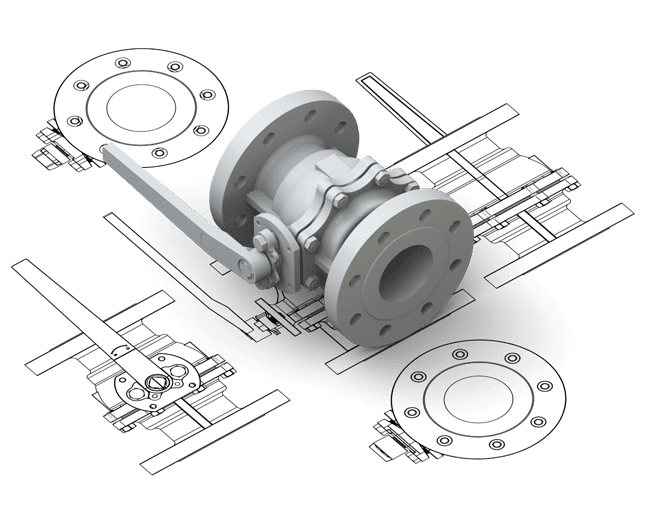

Design & Engineering Strategy

Create 2D and 3D Rendered concepts drawings that will be easy to understand and help make design decisions.

Rapid Design & Prototyping

If necessary, We will create 3D Printed samples of the housing for your approval, and test assembly with other devices, mainly for complex products

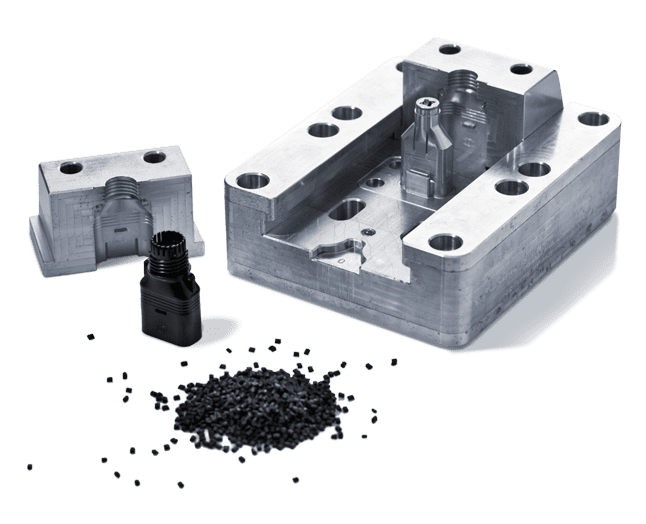

Break the mold

The development of product molds is a work that tests our production capacity. Our mold engineers have 20 years of mold design and production experience.

Therefore, the production of molds is the top priority of our work. It is also the step that takes the most time. The quality of the mold directly affects the qualified rate of the product and the speed of mass production.

Mold processing

The processing of the mold mainly includes the steps of design, wire cutting, heat treatment, etc. These steps are relatively time-consuming.

Test mold

We need to make sure that the product produced by the mold is what we want. Also make sure that it can be used to produce products in high volumes and over long periods of time.

Sample provided

Confirmation of samples is the most critical before mass production. Our mold engineers will make every effort to ensure the stability and high quality of the mold. So as to ensure that the samples made meet the requirements.

Samples are also a bridge to build trust and long-term cooperation between us and customers, and it will determine whether customers place orders to us.

Sample Delivery

The completion of the sample marks the end of product design and development , and also marks the landing of our production process and production process.

Sample Confirmed

Send the sample to the customer for confirmation, when the customer provides modification suggestions, we will make a second proofing until the customer is satisfied.

Production

Our goal is to make sure you understand every element of your product and how it will be made. Fully working samples are provided to make sure everything is correct before mass production. Manufacturing begins once you approve all the final design, materials, and components.

Various testing and certification are provided as needed or requested. We will guide you through the necessary steps to complete ROHS, CE, UL, VDE, and other certifications as needed or required.

Manufacturing Strategy

Receive and test components slated for production (Steel, standard parts, machined parts, etc.) Once approved and tested for fit, secure necessary quantity to complete the entire project.

Tooling, Samples, Mass Production

Mass production can commence once approval is received for products and packaging (when applicable). When requested, apply for certifications with appropriate agencies once the first units start coming off the production line.

Recognition

We create products that people want, it’s as simple as that. We want to make sure that the products customized for customers can stand out from their peers when installed in their equipment.

Delivery & Use Strategy

Assemble products into different packaging options as needed and fulfill directly to customers or individual locations as required.

Packaging

Create packaging that deals with the specific needs of our customers while making sure that it is safe and stable packaging.

What sets us apart from the competition?

Our ability to listen to our customers!

We work with small businesses and Fortune 500 companies to design and build amazing technology products for Promotional, Advertising, Retail, and OEM markets – fulfilling orders with short delivery times and complex technical specifications. We have earned the trust of thousands of clients, including these fine companies:

product category

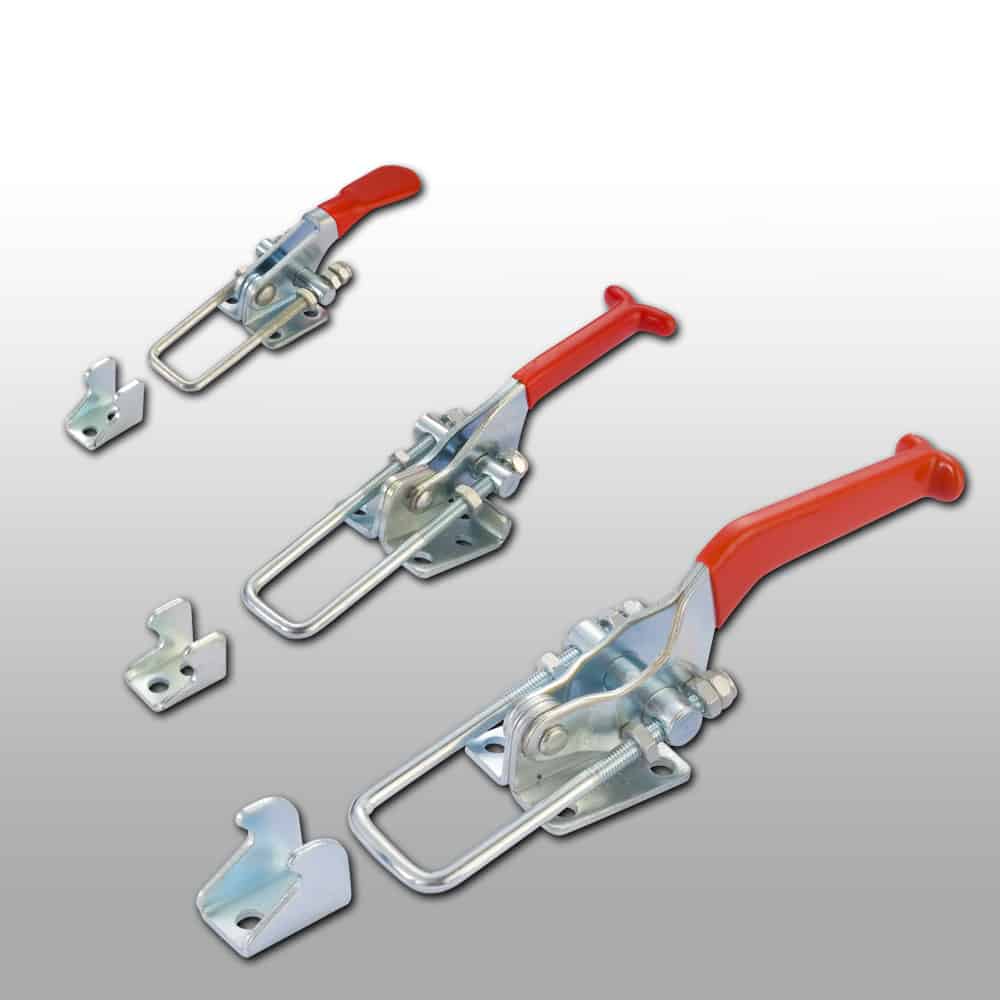

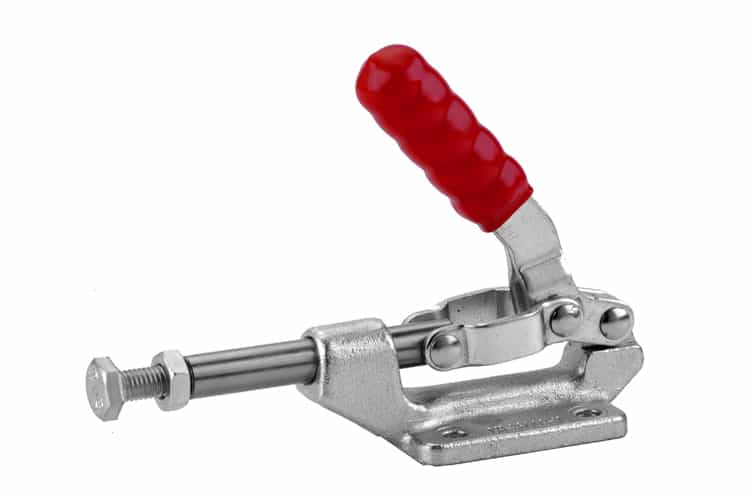

Our products mainly have 6 categories, namely Vertical Toggle Clamps, Horizontal Toggle Clamps, Push-pull Clamps, Latch Type Clamps, Pneumatic Toggle Clamps, Mailong Adjustable Toggle Clamps are identified by their handles or the way the product works.

If you can’t find the product you need in the product category, then customizing the product you need is a good choice. Product customization is our specialty, and we have professional design engineers and mold engineers who can quickly provide the best solution.

Horizontal Toggle Clamps

Latch-type Toggle Clamps

Pneumatic Toggle Clamps

Push-pull Toggle Clamps

Vertical Toggle Clamps

Factory introduction

Here will introduce you a general situation of the factory through text and photos, and you can also check the relevant information on the About Us page.

Why choose Mailong

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

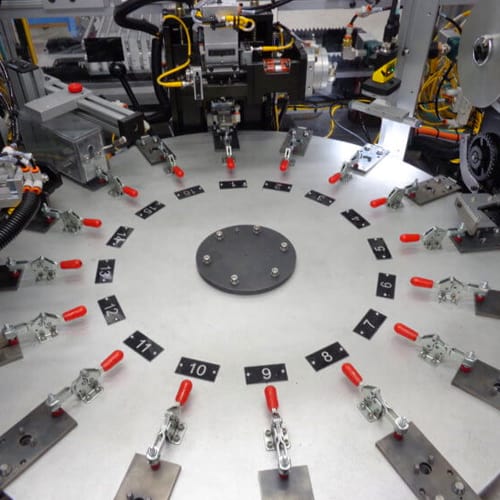

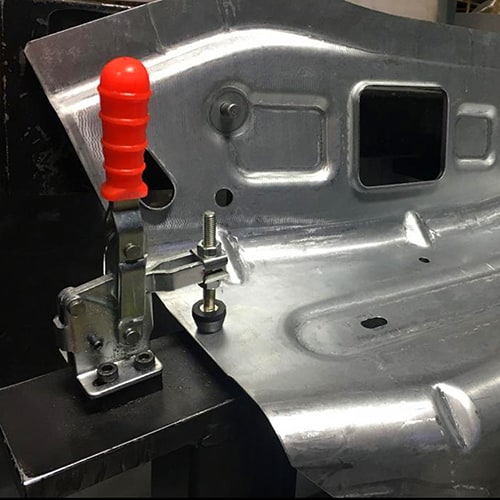

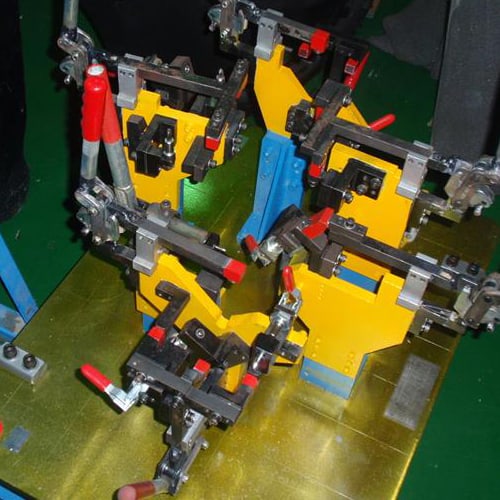

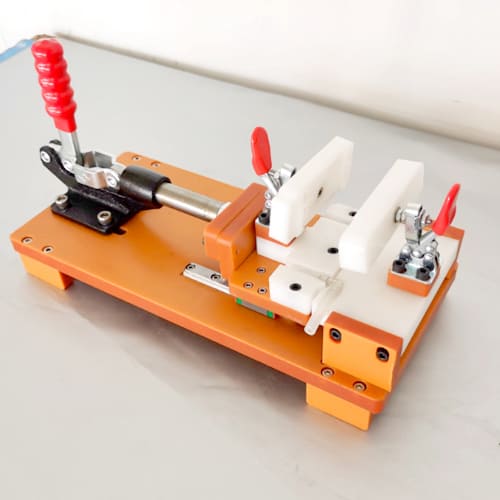

Applications

It is widely used in the production of freight equipment, the processing of automobiles, sheet metal, wooden products, and the processing of mechanical parts. The following are some actual usage scenarios of customers. If the usage scenarios are the same as yours, feel free to contact us: [email protected]