Tension Latches

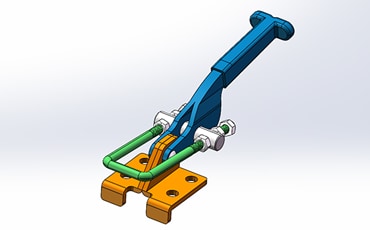

Tension Latches are a simple and easy-to-use product. Tension Latches are mainly made of iron and stainless steel. The dimensions are generally small.

Tension Latches are mainly used in various sheet metal cases, wooden boxes, and other equipment. There are adjustable tension latches, spring-loaded tension latches, and heavy-duty tension latches.

Other toggle clamps: Vertical Toggle Clamps, Horizontal Toggle Clamps, Push-pull Toggle Clamps, Latch-type Toggle Clamps, Pneumatic Toggle Clamps.

Stock product display of Mailong Tension Latches

Regular products are in stock, we can ship no matter the quantity

Table of Contents

For product customization of tension latches, contact us

Features of Mailong tension latches

The Mailong Vertical Toggle Clamps are manufactured from high-quality components and are designed for continuous use.

Mailong Tension Latches provide an adjustable, high-performance method ideal for securing machine and equipment parts that must be opened or removed frequently. Available in multiple sizes, these tension latches offer design flexibility for a variety of applications.

Want to know how we can do business? Contact Us!

How to Customize a tension latch?

We work fast. With the increasing number of customers approaching us, we have no other option but to prioritize speed. Custom your tension latches is simple. It is only 6 steps:

Our advantage about Customizing tension latches

Why not customize and make your product stand out among your peers, we can do it

Rich experience in customizing tension latches

We have been in the field of product customization for 20 years and have accumulated rich experience in the process of product customization. Our mold masters have been engaged in mold production for more than 10 years.

In the process of communicating with customers, they can quickly understand the real needs of customers and provide the best-customized solutions.

Complete software and hardware equipment

Our software and hardware are well-equipped, and our workers are professional. Whether improving an existing product or designing a new product, it can be delivered in the shortest time possible.

Because a lot of the preparatory work has been completed. For example, some parts can be used universally, and no need to make molds.

3D simulation of actual usage

We will provide customers with a 3D simulation map, so that customers can intuitively see the situation of the customized products in the actual use process.

This makes it easy for customers to make decisions and even identify areas for improvement

Save time and cost for customers

Because we have been engaged in the design of vertical toggle clamps, designers can quickly understand the needs of customers, and the communication efficiency is very high.

Maybe the customer’s problem has been solved in the previous customer, then we can directly provide the customer with a solution reference to save costs.

Great location

Factory location World famous manufacturing city: Dongguan, a coastal city with convenient transportation, is famous all over the world for its strong manufacturing industry.

All production materials can be quickly gathered, greatly reducing the production cycle of the entire product, so as to quickly deliver products to customers

Product quality assurance

Our products have quality assurance and can provide customers with product quality reports, material certificates, SGS reports and CE certification, and other related documents.

We need to ensure that every steel plate entering the workshop needs to have material certification documents to ensure that there is no problem with our materials.