Facing the multitude of tools available, identifying the right toggle clamp can be a challenging endeavor. Given their pivotal role in a wide array of tasks, ensuring you select the appropriate toggle clamp is of paramount importance.

Choosing the right toggle clamps depends on several factors including their specific application, the direction of force applied, and spatial constraints. Additionally, considerations such as holding capacity, operational speed, material durability, safety features, and budget play pivotal roles in the decision-making process.

Armed with insights and clarity, this guide aims to demystify the process, helping you make a decision with confidence. So, let’s delve in.

Consider the Application

The first step in your selection journey is discerning the exact application. Are you dealing with a project that requires rapid joining and releasing? Or perhaps you need a clamp that caters to both tensioning and compressing actions?

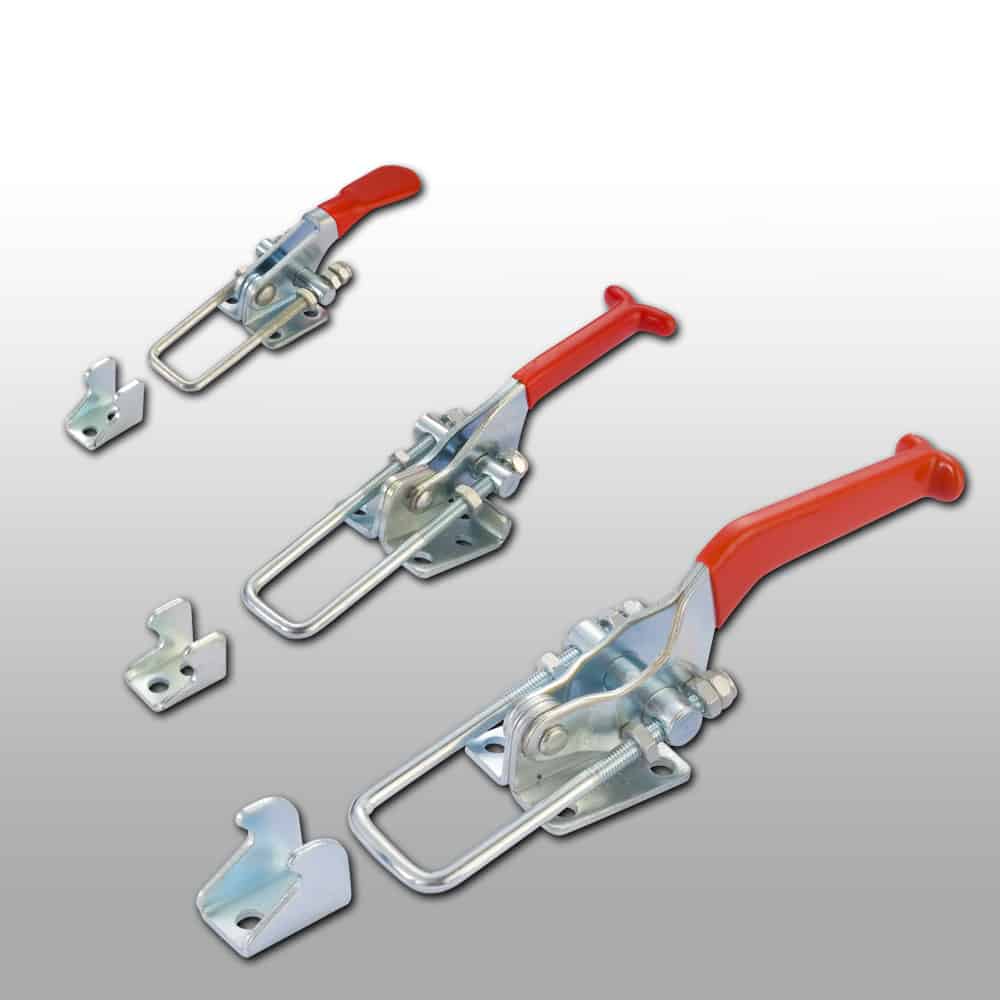

If it’s the former, latch-type toggle clamps might be your best bet, designed specifically for tasks demanding swift operations. However, if your project involves both pushing and pulling, the versatility of push-pull toggle clamps might be more suitable.

Determine the Force Direction

Understanding the force direction is crucial. Some projects need a force applied downward, while others might need lateral pressure.

Vertical toggle clamps specialize in downward pressure, making them ideal for tasks that demand strong downward force. On the other side of the spectrum, horizontal toggle clamps exert pressure in a direction parallel to their mounting surface, perfect for workspaces where height might be a constraint.

Space Constraints

Space is often a limiting factor. Certain environments might not offer the luxury of height, restricting the use of some clamps.

Horizontal clamps can be particularly handy in such scenarios due to their sideward movement. However, if you have more vertical room to play with, but need a clamp that can cater to both pushing and pulling, push-pull clamps offer a more fitting solution. Assess your workspace meticulously before making a decision.

Assess Holding Capacity

The holding capacity of a clamp determines the force it can comfortably handle. It’s a critical metric, dictating both efficiency and safety.

Opting for a clamp with a holding capacity that aligns with your project’s needs is paramount. It ensures that the clamp can endure the applied force, safeguarding against potential mishaps and ensuring a smooth operation.

Speed and Automation Needs

For projects leaning towards automation or those demanding rapid operations, the regular manual clamps might not suffice.

Pneumatic toggle clamps, which operate on compressed air, offer both speed and precision, characteristics vital for automated setups. Their ability to maintain consistent performance reduces room for errors, optimizing the overall process.

Durability and Material

A clamp’s longevity often hinges on its construction material. Different materials offer varying degrees of durability and resistance to external factors.

For instance, stainless steel clamps are renowned for their resistance to rust, ensuring a longer lifespan, especially in moisture-prone environments. It’s essential to weigh the clamp’s material against the environment it’ll be used in, ensuring you get the most out of your investment.

Safety Features

Safety is paramount. While toggle clamps are inherently designed for secure operations, some come with added safety features, enhancing their reliability.

Certain clamps boast safety locks that deter unintended releases. Such features, although might seem trivial, play a crucial role in ensuring the workpiece stays firmly in place, bolstering safety.

Budget Constraints

Budget is a defining factor in any purchase decision. While the allure of cost-saving is strong, it’s pivotal to strike a balance between cost and quality.

While some premium clamps might seem expensive upfront, their durability and efficiency can offer long-term savings. It’s always advisable to view such investments through the lens of long-term value rather than just initial cost.

Conclusion

The realm of toggle clamps, although diverse, becomes navigable with the right knowledge. By understanding your requirements and aligning them with the various clamp features, you can make an informed choice, ensuring both efficiency and safety.

For those scouting for premium toggle clamps, MAILONG stands out as a trusted name. As professional manufacturers, our comprehensive stock ensures swift deliveries. Please feel free to contact us for a quotation.

You might also be interested: