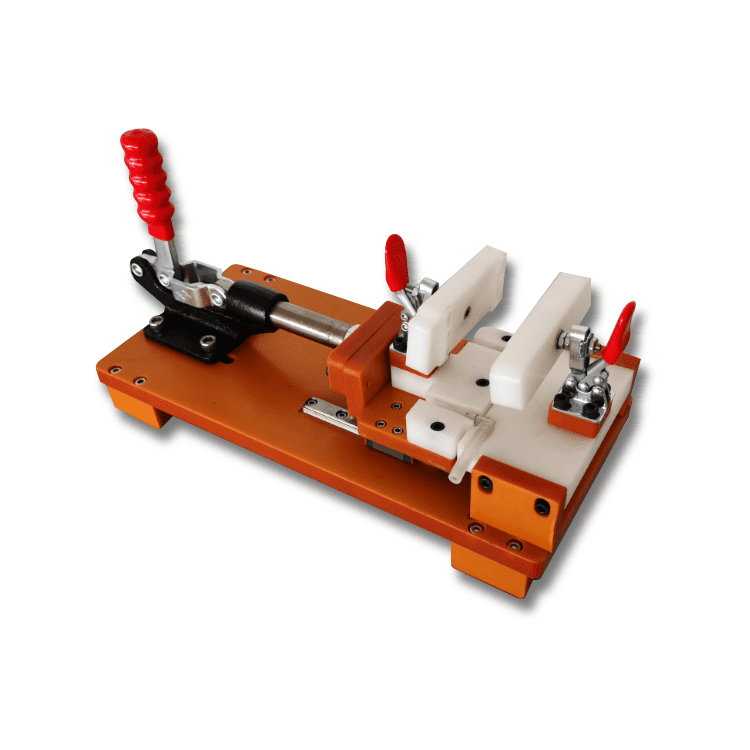

Toggle clamp linkages are an essential component of many clamping systems, providing a reliable and efficient means of holding workpieces in place. Whether building a new clamp from scratch or modifying an existing design, a properly designed and assembled toggle clamp linkage is essential for ensuring safe and effective operation. In this essay, we will explore the key considerations involved in designing and building toggle clamp linkages, and provide answers to common questions related to this important component of clamping systems.

How do I design and build my own toggle clamp linkage?

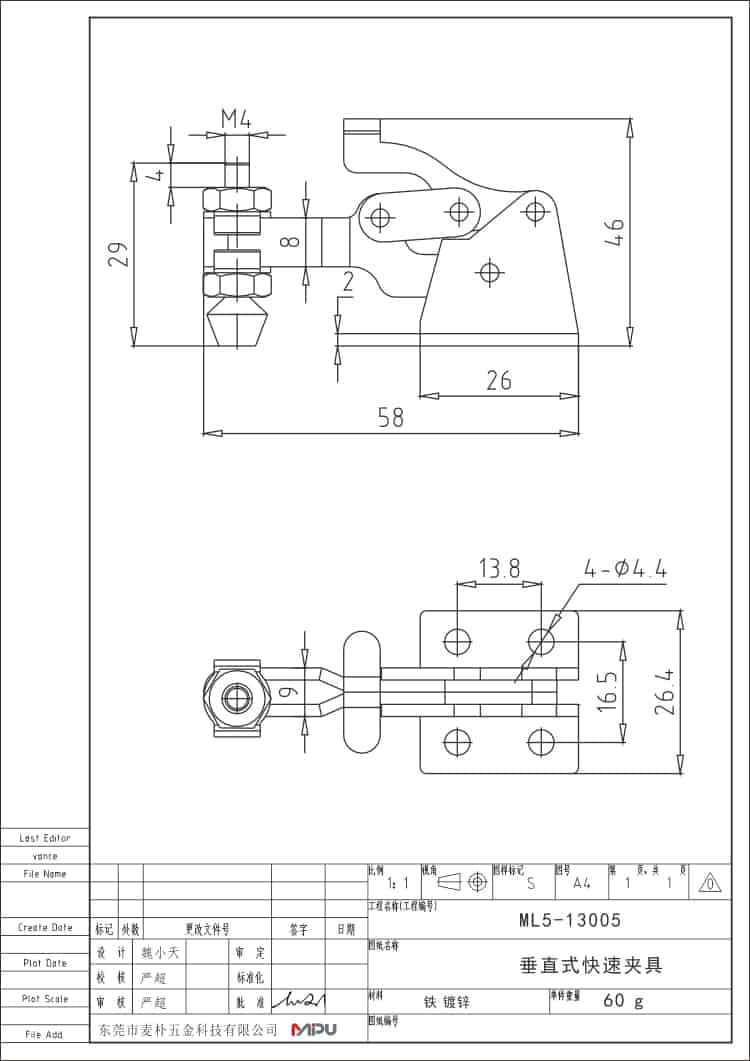

When designing and building a toggle clamp linkage, there are several factors to consider. The first is the amount of force required to hold the workpiece in place. This will determine the size and strength of the linkage components, including the lever arm and the pivot pins. Next, you’ll need to determine the best placement of the linkage on the clamp base and the clamp arm to ensure that it applies the necessary clamping force in the desired location.

Once you have a design in mind, it’s important to carefully select the materials you’ll use for the linkage components. Steel is a common choice, as it is strong and durable, but an aluminum or other lightweight metals may be suitable for smaller clamps. Finally, when assembling the linkage, be sure to use proper techniques and fasteners to ensure that all components are securely connected and can withstand the clamping force.

If this is a difficult matter for you, you can contact our professional staff to help you. MAILONG is a professional toggle clamps supplier and can provide you with professional assistance.

What are the best materials to use for making toggle clamp linkages?

The best materials for toggle clamp linkages will depend on a few factors, including the size and strength requirements of the clamp, the intended use of the clamp, and the desired durability of the linkage. In general, steel is a common choice for larger clamps and for clamps that will be used in industrial or heavy-duty applications. Stainless steel may also be a good option, as it is resistant to corrosion and can withstand harsh environments.

For smaller clamps or clamps that will be used in more lightweight applications, aluminum or other lightweight metals may be suitable. Plastic or nylon components can also be used in some cases, especially for components that do not bear the main clamping force. Ultimately, the choice of materials will depend on the specific requirements of the clamp and the available materials.

What are the most common mistakes to avoid when building toggle clamp linkages?

One of the most common mistakes when building toggle clamp linkages is to use components that are not strong enough to withstand the clamping force. This can lead to failure of the linkage, which can damage the workpiece or cause injury to the user. Another mistake is to use components that are not properly aligned, which can cause the trendy toggle clamps to apply force in the wrong direction or cause the linkage to bind.

It’s also important to ensure that all components are securely fastened, as loose connections can cause the clamp to slip or fail entirely. Finally, it’s important to carefully consider the design of the linkage and to test the clamp before use to ensure that it is capable of applying the necessary clamping force in the desired location.

What are some good resources for learning about toggle clamp linkage design?

There are a variety of resources available for learning about toggle clamp linkage design. Online forums and communities can be great source of information and advice, as they allow you to connect with other clamp builders and ask questions about specific designs or techniques. You can also find tutorials and instructional videos on sites like YouTube, which can provide step-by-step guidance on building a toggle clamp linkage.

In addition, books and technical manuals can provide in-depth information on the design and construction of toggle clamp linkages, including the use of different materials, the calculation of necessary forces, and the selection of appropriate components. Finally, if you’re working on a complex or custom design, it may be helpful to consult with an experienced engineer or machinist who can provide specialized advice and guidance.

Can I modify an existing toggle clamp to create a custom linkage?

Yes, it is often possible to modify an existing toggle clamp to create a custom linkage. This can be a cost-effective solution, as it allows you to leverage the existing base and arm of the clamp while customizing the linkage components to suit your specific needs. To modify a toggle clamp, you will need to carefully assess the existing design and determine which components can be reused and which will need to be replaced or modified.

Common modifications include replacing the pivot pins, adjusting the position of the clamp arm, and adding or modifying the lever arm. Depending on the extent of the modifications required, you may need to use specialized tools and techniques, such as welding or machining, to create the necessary components.

It’s important to keep in mind that modifying an existing clamp can be more complex than building a new one from scratch, as it requires a thorough understanding of the existing design and how the modifications will affect its operation. Additionally, modifications can sometimes compromise the strength or durability of the clamp, so it’s important to carefully assess the suitability of the modified design before putting it into use.

Based on my personal experience, designing and building toggle clamp linkages requires careful consideration of several factors, including the necessary force, materials, and proper assembly techniques. Common mistakes include using components that are not strong enough, misaligning components, and not testing the clamp before use. Good resources for learning about toggle clamp linkage design include online communities, tutorials, and technical manuals, and modifying an existing clamp can be a cost-effective solution but requires careful assessment and modification of the existing design.

If you encounter any problems during the production process, you can contact us at any time.