Toggle clamps are a popular type of clamping device used in woodworking to hold workpieces securely in place during cutting, sanding, and other operations. They are simple to use and provide a strong, reliable grip, making them an essential tool for any woodworker.

What are toggle clamps and how do they work for woodworking?

Toggle clamps, also known as welding toggle clamps or woodworking toggle clamps, are mechanical clamping devices that use a linkage system to hold workpieces securely in place. They consist of a fixed base, a movable clamping arm, and a handle or lever that is used to operate the clamp.

When the handle is pushed down, the clamping arm moves towards the workpiece and applies pressure, holding the workpiece firmly in place. The linkage system used in toggle clamps allows them to generate high clamping forces with very little input force from the user.

What are the different types of toggle clamps available for woodworking?

There are several different types of toggle clamps available for woodworking, each designed for specific applications. Some of the most common types include:

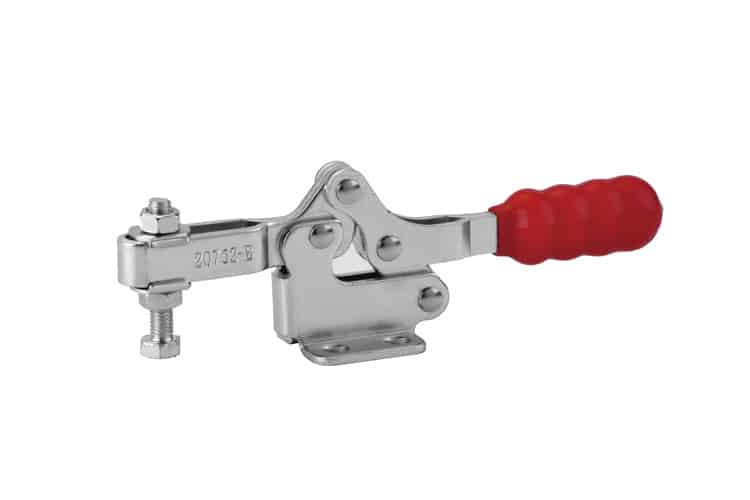

Horizontal toggle clamps: These clamps have a horizontal clamping arm that moves in a straight line toward the workpiece. They are ideal for holding flat or rectangular workpieces.

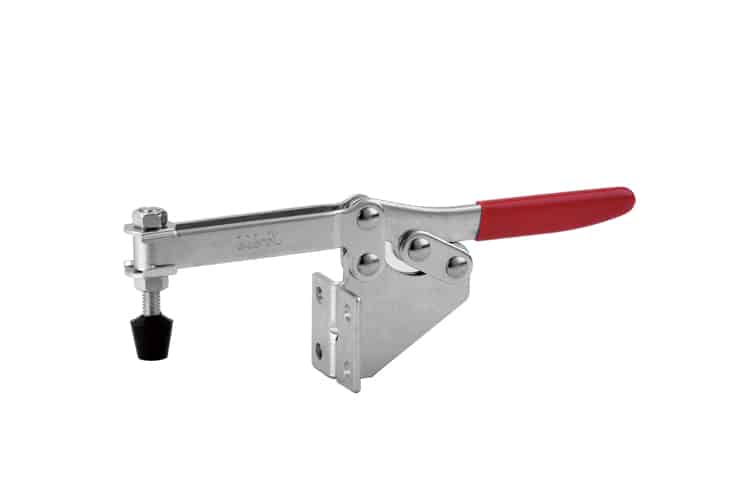

Vertical toggle clamps: These clamps have a vertical clamping arm that moves up and down to hold the workpiece. They are often used for holding round or irregularly-shaped workpieces.

Push-pull toggle clamps: These clamps are designed to apply pressure in both the pushing and pulling directions, making them ideal for holding workpieces that need to be pulled up against a stop or fence.

Latch-type toggle clamps: These clamps use a latch mechanism to hold the workpiece in place. They are often used for clamping jigs or fixtures to a workbench.

Welding toggle clamps: They are designed to hold metal pieces in place during welding, providing a secure and precise hold.

How do I select the right size toggle clamp for my woodworking project?

When selecting a toggle clamp for your woodworking project, it is important to consider the size and shape of the workpiece you will be clamping. The clamping force required will also depend on the material being used and the type of operation you will be performing.

To determine the appropriate size of the toggle clamp, measure the thickness of the workpiece and choose a clamp that can accommodate that thickness. The maximum clamping force of the clamp should also be considered, as this will determine the amount of pressure that can be applied to the workpiece. If this is a difficult task for you, you can contact our MAILONG sales staff. They can guide the selection of the correct size.

Can toggle clamps be used for holding workpieces of different shapes and sizes?

Yes, toggle clamps can be used to hold workpieces of different shapes and sizes. However, it is important to choose the right type of clamp for the job. Horizontal toggle clamps are ideal for holding flat or rectangular workpieces, while vertical toggle clamps are better suited for round or irregularly-shaped workpieces.

Push-pull toggle clamps are versatile and can be used for a variety of applications, including holding workpieces of different shapes and sizes. Latch-type toggle clamps can be used to hold jigs and fixtures in place.

How do I properly install and use toggle clamps for woodworking?

To install a toggle clamp, first, mount the clamp to a solid surface such as a workbench or jig. The base of the clamp should be firmly attached to the surface to ensure a stable hold. Next, adjust the position of the clamping arm so that it is in the correct location to hold the workpiece.

To use the toggle clamp, engage the handle or lever and apply pressure to the workpiece. It is important to ensure that the workpiece is securely held in place before beginning any cutting or sanding operations.

What are the advantages of using toggle clamps over other types of clamps in woodworking?

One of the main advantages of using toggle clamps in woodworking is their ability to generate high clamping forces with very little input force from the user. This makes them ideal for holding workpieces securely in place, even during heavy cutting or sanding operations.

Toggle clamps also provide a quick and easy way to hold workpieces, as they can be engaged and disengaged quickly and easily with one hand. This allows woodworkers to focus on the task at hand without having to worry about adjusting the clamp.

In addition, toggle clamps are versatile and can be used to hold a wide range of workpiece shapes and sizes. They are also generally more affordable than other types of clamps, making them an accessible tool for woodworkers of all skill levels.

Where can I buy high-quality toggle clamps for woodworking?

High-quality toggle clamps can be purchased from a variety of sources, including woodworking supply stores, hardware stores, and online retailers. Some popular brands of toggle clamps for woodworking include Bessey, De-Sta-Co, and Kreg.

When shopping for toggle clamps, be sure to read reviews and compare prices to ensure you are getting a quality product at a fair price.

What maintenance is required for toggle clamps used in woodworking?

Toggle clamps used in woodworking typically require very little maintenance. However, it is important to keep them clean and free from sawdust and debris, as this can affect their performance.

If the clamp becomes stiff or difficult to operate, it may need to be lubricated with a small amount of oil. The linkage system and other moving parts should also be checked periodically to ensure they are in good condition.

Can toggle clamps damage the workpiece or affect its finish?

While toggle clamps are generally safe to use with most types of wood, they can sometimes leave marks or indentations on the workpiece if too much pressure is applied. This can be prevented by placing a scrap piece of wood between the clamp and the workpiece.

In addition, toggle clamps with rough or uneven surfaces can sometimes scratch or mar the surface of the workpiece. To prevent this, choose a clamp with a smooth surface or wrap the clamp in a soft material such as felt or foam.

Are there any safety precautions that should be taken when using toggle clamps in woodworking?

When using toggle clamps in woodworking, it is important to follow basic safety precautions to prevent injury. Always wear eye protection and keep your hands and fingers away from the cutting area. Ensure the clamp is securely attached to the workbench or jig and that the workpiece is firmly held in place before beginning any cutting or sanding operations.

In addition, it is important to use the right size and type of clamp for the job to ensure a secure hold. Using a clamp that is too small or too large can result in a weak hold or damage to the workpiece.

Overall, toggle clamps are a useful and versatile tool for woodworkers of all skill levels. By choosing the right size and type of clamp for the job and following basic safety precautions, woodworkers can achieve a secure and reliable hold on their workpieces, allowing them to complete their projects with precision and ease.