In every industrial setting, there are tools and devices whose importance and functionality often get overshadowed by more prominent machinery. Toggle clamps, though humble in appearance, play a pivotal role in numerous applications, ensuring workpieces remain firmly in place during operations.

These unique clamps operate through a combination of leverage and over-center locking mechanisms. This ensures that once a workpiece is clamped into position, it remains stationary, irrespective of external forces, making the work environment both efficient and safe.

Let’s dive into the intricate world of toggle clamps, exploring the principles behind their operation and the reasons behind their widespread utility.

Basic Principle of Toggle Clamps

At the heart of every toggle clamp lies a foundational mechanical principle. As the handle is moved, and the clamp goes past its central pivot point, an ‘over-center’ locking mechanism is triggered. This causes the clamp to ‘lock’ in place, providing an unyielding grip on the workpiece.

Further, the clamp will steadfastly remain in this locked position until manually released by the operator. The interaction between the pivot point, handle, and clamping arm ensures this stability, providing a reliable grip that safeguards both the workpiece and the worker.

Components of a Toggle Clamp

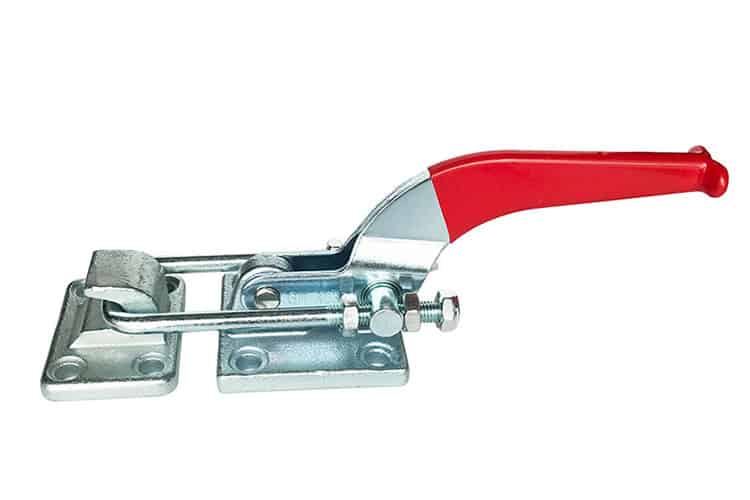

The efficacy of toggle clamps can be attributed to their distinct components. Primary among these are the handle, clamping arm, pivot pin, and base. The handle acts as the point of interaction for the operator, linked directly to the clamping arm via the pivot pin. This intricate connection is the heart of the clamp’s operation, dictating force distribution and leverage.

The base, while less glamorous, is equally vital. It serves as the anchor, ensuring the clamp remains securely fastened to the working surface. Its design, often heavy and robust, contributes significantly to the clamp’s overall stability.

Types of Toggle Clamps

Diverse applications call for a range of toggle clamps, each designed for specific tasks. Push-pull clamps, for instance, move linearly and are suited for tasks requiring bidirectional movements. In contrast, latch clamps are designed to pull and lock the clamping arm, making them ideal for securing doors or lids.

There are also specialized variants like the hold-down clamps, which exert a downward force on the workpiece, and hook clamps, characterized by their unique hook-shaped clamping arms, catering to specific industrial needs.

Mechanism of Action

The brilliance of the toggle clamp’s design lies in its over-center locking mechanism. As the clamp crosses its pivot point during operation, it employs the forces applied by the user to stay locked. This intentional design ensures that once engaged, the clamp requires a significantly greater force to be unlocked, guaranteeing safety and precision during its operation.

Advantages of Toggle Clamps

These clamps are not just about their locking mechanisms; they come with a host of advantages. Rapid clamping and unclamping save invaluable time during workflows. Their consistent clamping force eliminates variability, ensuring standardization across operations. Moreover, their design versatility means they can be employed in a myriad of applications, irrespective of the industry.

Common Applications

From the automotive world to the intricate realm of electronics, toggle clamps are ubiquitous. They find purpose in welding, where they hold components in place for precise joins. In electronics, they secure circuit boards firmly during soldering processes. Their adaptability is a testament to their design excellence, proving their value across diverse sectors.

Maintenance and Safety

Like all mechanical devices, toggle clamps demand regular maintenance for optimal performance. It’s vital to frequently inspect for wear, particularly at the pivot points, and ensure they are lubricated to prevent undue wear and tear. Furthermore, training operators in the correct usage can prevent over-tightening, safeguarding both the clamp and the workpiece from potential damage.

Conclusion

In the vast landscape of industrial tools, toggle clamps, with their meticulous design and wide-ranging applications, have carved a niche for themselves. By understanding their operational principles and ensuring their regular upkeep, one can harness their full potential, enhancing both efficiency and safety in workspaces.

You might also be interested: