Toggle clamps are essential tools that are widely used in various industries, including woodworking, metalworking, and automotive manufacturing. They are mechanical devices that are designed to hold objects securely in place during cutting, drilling, sanding, milling, and other machining processes. They are easy to use and highly effective in preventing workpieces from slipping or moving out of position, which can compromise the quality and safety of the work.

In this essay, we will discuss how to use toggle clamps, including the different types of toggle clamps, their features and benefits, and the proper techniques for installing and operating them.

Types of Toggle Clamps

Toggle clamps come in various types, each designed to suit specific applications and workpiece sizes. The following are some of the most common types of toggle clamps:

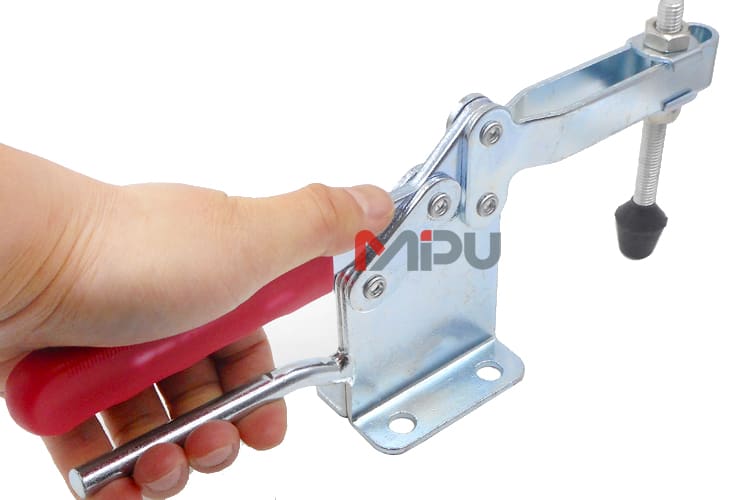

Vertical toggle clamps – These are the most popular type of toggle clamps and are designed for clamping objects from the top. They have a vertical holding capacity, which means they can clamp workpieces securely by pulling them downwards.

Horizontal toggle clamps – These clamps are ideal for clamping objects from the side. They are suitable for applications that require horizontal clamping pressure, such as woodworking and metalworking.

Push-pull toggle clamps – These are versatile clamps that can apply both pushing and pulling forces. They are designed for clamping workpieces in tight spaces and can be used in a variety of applications.

Welding toggle clamps – These clamps are designed specifically for welding applications and provide a secure grip on the workpiece during the welding process.

Features and Benefits of Toggle Clamps

Toggle clamps are designed with unique features that make them ideal for different applications. Some of the features and benefits of toggle clamps include:

Easy to use –Using toggle clamps is a very simple process. They have a simple mechanism that allows users to lock and release the clamps quickly.

High clamping force – Toggle clamps provide a high clamping force that holds workpieces securely in place. They can prevent workpieces from slipping or moving during machining, ensuring consistent quality and safety.

Adjustable clamping force – Some toggle clamps have an adjustable clamping force, which allows users to adjust the pressure according to the application’s needs. This feature can help prevent damage to delicate or fragile workpieces.

Versatile – Toggle clamps are versatile and can be used in various applications, including woodworking, metalworking, automotive manufacturing, and other machining processes.

Installing Toggle Clamps

Installing toggle clamps is a simple process that requires minimal tools and skills. The following are the steps for installing toggle clamps:

Determine the location – Identify the area where you want to install the toggle clamp. Ensure that the area is flat and even to ensure the clamp’s stability and effectiveness.

Mark the spot – Use a pencil or marker to mark the spot where you want to install the toggle clamp. Ensure that the mark is visible and accurate to avoid mistakes during installation.

Drill the hole – Use a drill to create a hole in the marked spot. The hole’s diameter should be slightly smaller than the toggle clamp’s screw to ensure a tight fit.

Install the clamp – Insert the toggle clamp’s screw into the drilled hole and tighten it until it is secure. Ensure that the clamp’s base is flat against the workpiece to provide maximum stability.

Operating Toggle Clamps

Operating toggle clamps is a straightforward process that involves minimal effort and skills. The following are the steps for operating toggle clamps:

Position the workpiece – Position the workpiece in the desired location and ensure that it is level and stable. Adjust the clamp – If the clamp has an adjustable pressure feature, adjust it according to the workpiece’s thickness and fragility. Ensure that the clamp is positioned in the correct location for maximum stability.

Lock the clamp – Pull the clamp’s handle to lock it into place. Ensure that the clamp is securely locked and holding the workpiece in place.

Perform the machining process – Once the clamp is locked into place, perform the machining process. Ensure that the clamp is holding the workpiece securely and preventing it from moving or slipping.

Release the clamp – After the machining process is complete, release the clamp by pushing the handle down. Ensure that the clamp is fully released before removing the workpiece.

Maintenance of Toggle Clamps

Proper maintenance of toggle clamps is essential to ensure their longevity and effectiveness. The following are some maintenance tips for toggle clamps:

Clean regularly – Toggle clamps should be cleaned regularly to prevent dust, dirt, and debris from accumulating on them. Use a clean cloth to wipe down the clamps after each use.

Lubricate moving parts – The moving parts of toggle clamps should be lubricated regularly to ensure smooth operation. Use a light oil or lubricant to lubricate the clamp’s moving parts.

Check for wear and tear – Regularly check the toggle clamps for wear and tear, such as cracks or broken parts. Replace any worn or damaged parts immediately to prevent accidents or injuries.

Store properly – Toggle clamps should be stored in a dry and clean location to prevent rust and corrosion. Keep them in a toolbox or storage container to protect them from dust and debris.

Based on my personal experience, toggle clamps are essential tools for various industries, including woodworking, metalworking, and automotive manufacturing. They provide a high clamping force that holds workpieces securely in place, preventing slipping or moving during machining processes. Toggle clamps are easy to install, operate, and maintain, and they are versatile and suitable for a wide range of applications. By following the proper techniques for installing, operating, and maintaining toggle clamps, you can ensure their longevity and effectiveness, providing a safer and more efficient work environment.