Horizontal toggle clamps are an essential tool in the manufacturing, woodworking, and metalworking industries. They are a type of mechanical clamp that is used to secure objects in place during various stages of production or assembly. This essay aims to provide a comprehensive guide to the uses, differences, and operation of horizontal toggle clamps.

What is a horizontal toggle clamp used for?

Horizontal toggle clamps are used to secure objects in place during various stages of production or assembly. They are commonly used in manufacturing, woodworking, and metalworking industries to hold workpieces securely while drilling, cutting, or sanding. Horizontal toggle clamps are also used in various applications, such as welding, stamping, and molding.

What is the difference between horizontal and vertical toggle clamps?

The primary difference between horizontal and vertical toggle clamps is the direction of the clamping force. Horizontal toggle clamps apply force in a horizontal direction, while vertical toggle clamps apply force in a vertical direction. The choice of clamp depends on the application, and the direction of the clamping force required.

Horizontal toggle clamps are more commonly used in applications where the force needs to be applied horizontally. They are also used when there is limited space between the clamped object and the work surface. Vertical toggle clamps, on the other hand, are more commonly used when the force needs to be applied vertically, such as when clamping objects to a vertical surface.

How do toggle clamps work?

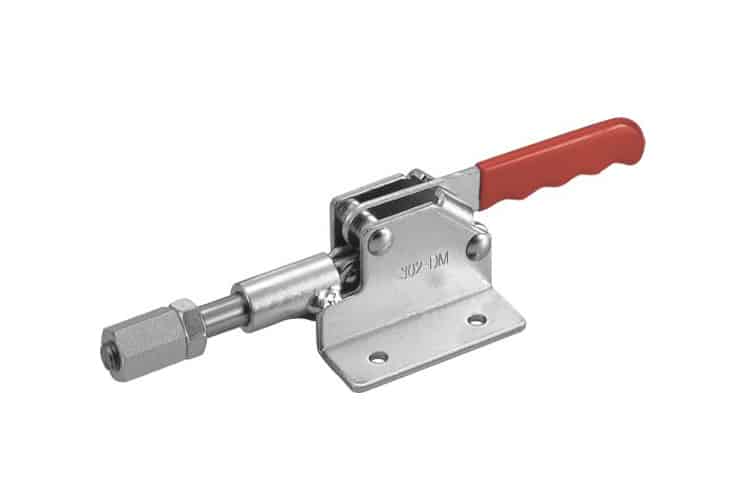

Toggle clamps are mechanical clamps that use a lever and pivot to apply clamping force to an object. The basic design of a toggle clamp consists of a handle, a toggle link, and a clamping plate.

The toggle link is a two-piece mechanism that consists of a fixed link and a moving link. The fixed link is attached to the clamp body, while the moving link is connected to the clamping plate. When the handle is pulled down, the moving link rotates around the pivot point, which in turn, moves the clamping plate toward the workpiece.

The toggle clamps work on the principle of leverage. When the handle is pulled down, the force is transferred to the toggle link, which increases the clamping force. As the clamping force increases, the toggle link moves to a position of stability, where it can hold the clamping plate securely in place.

Pneumatic clamps for woodworking also use this principle. We have many other types of clamps, most of which are based on a similar principle.

How do you use toggle clips?

Using toggle clips is a simple and straightforward process. First, position the workpiece between the clamping plate and the work surface. Next, pull the handle down to apply the clamping force. Ensure that the clamping plate is securely holding the workpiece in place. To release the clamp, simply lift the handle up, and the clamping force is released.

It is important to ensure that the toggle clamp is correctly sized for the application and that the clamping plate is securely holding the workpiece in place. It is also essential to use toggle clamps in the correct direction and to ensure that the clamping force is applied in the direction required for the application.

Based on my personal experience, horizontal toggle clamps are a vital tool in the manufacturing, woodworking, and metalworking industries. They are easy to use, and their simple design makes them a reliable and efficient clamping solution. Understanding the uses, differences, and operation of horizontal toggle clamps can help individuals and businesses achieve higher levels of productivity, efficiency, and success in their work.

MAILONG is a professional toggle clamps supplier. If you encounter any problems in the process of purchasing or using the Quick Clamp, you can also contact us directly.