In the modern assembly and manufacturing industry, one often overlooked yet vital component is the toggle clamp. What’s the buzz about these little devices, and why should one be concerned about where they come from?

Toggle clamps play an instrumental role in ensuring secure holding and clamping applications, and their suppliers dictate their quality, efficiency, and reliability.

As you journey through this article, we’ll unfold the importance of these suppliers and how they impact the industry.

What are Toggle Clamps Used For?

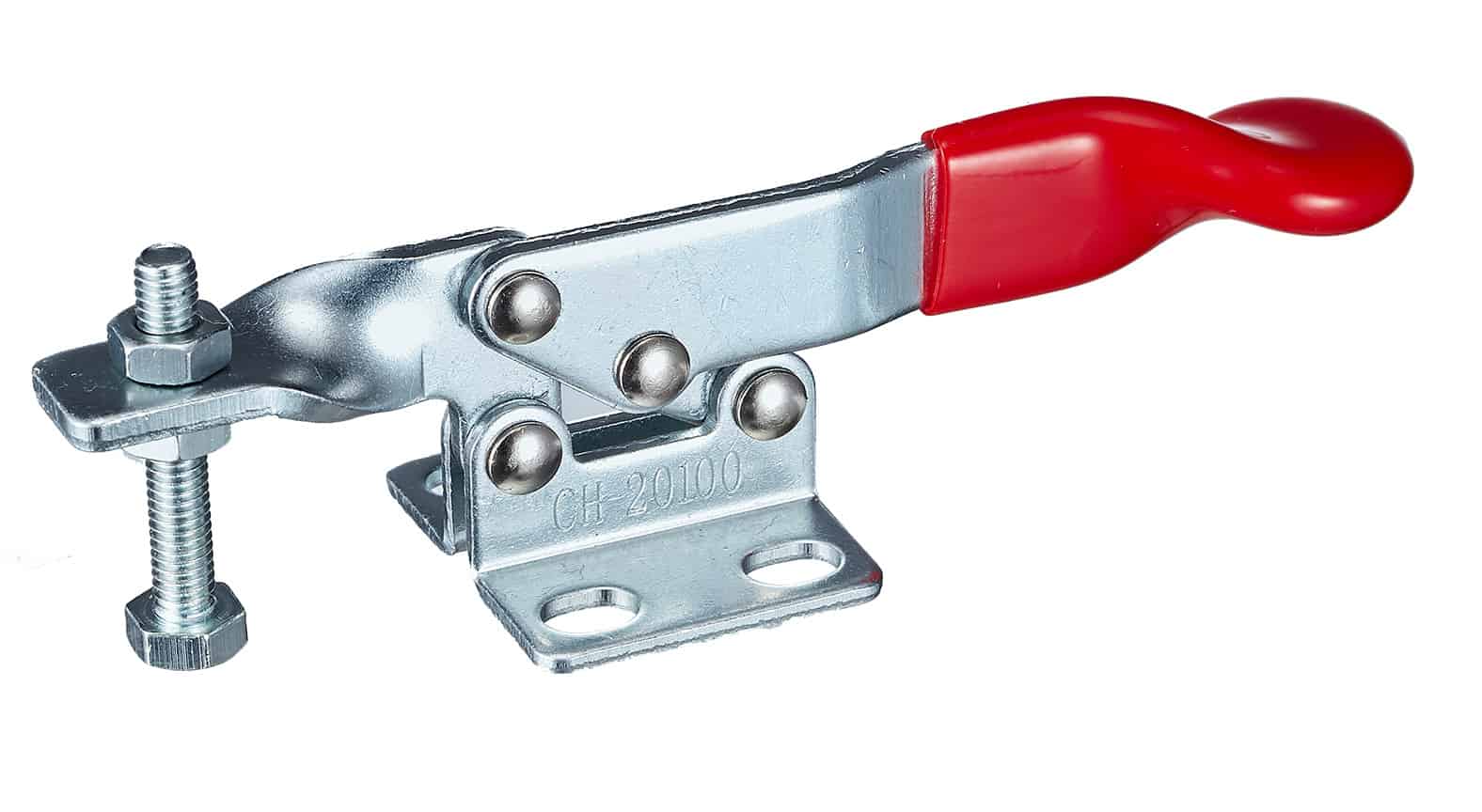

Toggle clamps, for the uninitiated, are quick-release devices widely used in both industrial and woodworking applications. Their primary purpose is to hold workpieces securely in place, ensuring precision and safety during processes like cutting, welding, and assembly.

Why Quality Matters in Toggle Clamps?

Imagine holding a piece of metal under a heavy machine for a high-pressure process. The toggle clamp’s reliability becomes paramount. Choosing high-quality toggle clamps reduces risks associated with equipment failures, ensuring that processes run smoothly and safely.

How Do Suppliers Impact Toggle Clamps’ Quality?

The quality of the toggle clamp is, to a large extent, determined by its supplier. They are responsible for sourcing the raw materials, overseeing the manufacturing process, and ensuring that each product meets industry standards.

A reputable supplier will guarantee consistent quality, whereas an unreliable one can result in variable product standards, which can lead to process inefficiencies or even accidents.

Are All Toggle Clamps The Same?

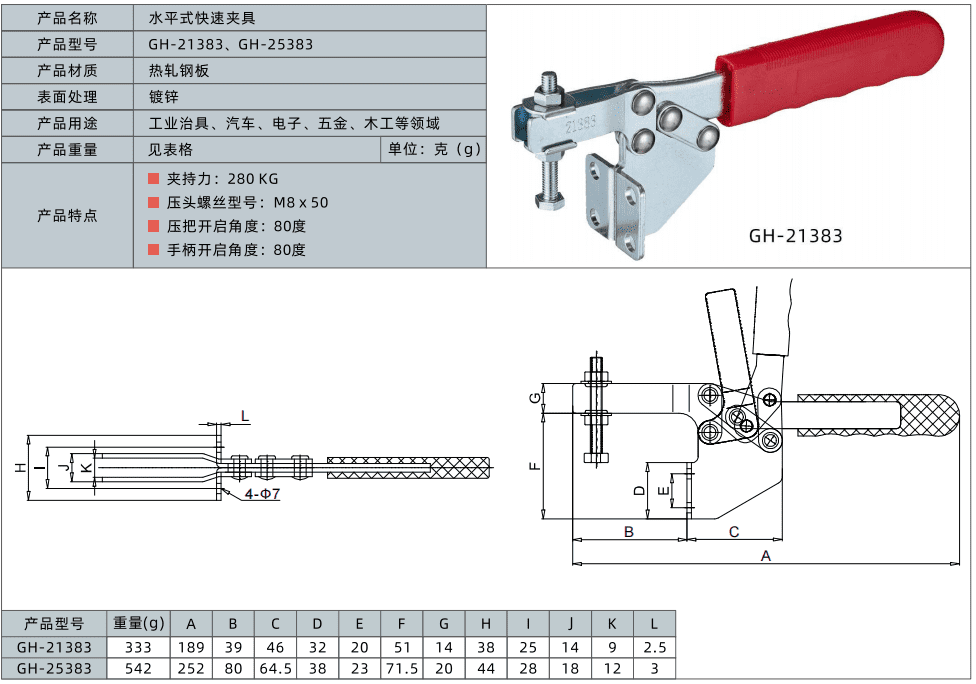

At a glance, one might be tempted to think that all toggle clamps serve the same function. However, delve deeper, and the variety becomes evident. Different tasks require different clamps, and a good supplier offers a diverse range to cater to specific industry needs.

How Do Suppliers Ensure Reliability?

Reliability in toggle clamps is not just about their build but also about their consistent performance over time. Suppliers ensure this reliability by adhering to stringent quality control processes, regular testing, and feedback loops from the end users.

What to Look for in a Toggle Clamps Supplier?

When seeking a supplier, it’s not just about the product but also the value-added services. A reliable supplier provides clear communication, timely deliveries, and post-purchase support. Additionally, certifications and accreditations can offer insights into their commitment to quality and industry standards.

Is Cost the Only Factor When Choosing a Supplier?

While pricing is a significant factor, it shouldn’t be the sole consideration. Sometimes, a lower upfront cost might mean compromises in quality, leading to more significant expenses down the line. It’s essential to weigh the balance between cost, quality, reliability, and service when choosing a toggle clamps supplier.

How Do Global Trends Impact Toggle Clamp Suppliers?

The world of manufacturing and assembly is continually evolving, with innovations, regulations, and environmental concerns shaping the industry’s landscape. Toggle clamps suppliers need to adapt to these changes, ensuring their products are both state-of-the-art and compliant with global standards.

Conclusion

Understanding the role and significance of toggle clamps suppliers is crucial for any industry relying on clamping applications. Their influence on quality, reliability, and safety cannot be overstated. By considering the various facets discussed, one can make informed decisions and ensure smooth, safe operations.

You might also be interested: