In the world of tools and equipment, there exists an unsung hero that doesn’t always get the recognition he deserves. Clamps play a crucial role in various fields, enabling professionals and hobbyists to hold objects securely for an array of purposes. This tool is a testament to the saying, “Holding things together is as essential as putting them together.”

Clamps are indispensable tools that are used to hold, secure, or fasten objects together to prevent movement or separation. They come in different shapes, and sizes, and are tailored for specific applications in diverse sectors, excluding furniture, architecture, and decoration.

With this primer in place, let’s delve into eight of the most common types of clamps, understanding their uniqueness and importance in distinct realms.

C-Clamp

Commonly shaped like the letter “C,” this clamp is a versatile tool, primarily known for its use in metalworking and woodworking. Its design allows for a wide opening to accommodate thicker materials.

With a screw mechanism at the top, users can adjust the width, ensuring a tight grip. Its primary advantage is its ability to apply concentrated pressure, making it perfect for welding or other tasks where precision is required.

Spring Clamp

Typically made of metal or plastic, spring clamps operate on a simple mechanism: a spring that applies pressure to the jaws. They’re quick to apply and remove, making them perfect for temporary holding tasks.

Their strength lies in their simplicity. They’re often used in photography for backdrop setup or in woodworking for glue-ups where the material needs to be held for a short duration.

Hose Clamp

Primarily used in automotive and home applications, hose clamps are designed to seal hoses onto fittings. They come in various styles, but the most common is the worm gear type, which tightens as you turn a screw.

This clamp ensures a watertight seal, essential in systems like car radiators or home plumbing. A faulty hose clamp can lead to leaks and potential system failures, highlighting their significance in such setups.

Locking Pliers

Also known as Vise-Grips, these pliers have a mechanism that allows them to lock in place, holding an object securely. They come with a lever, which when activated, applies consistent pressure on the item.

Predominantly used in metalworking and automotive repair, their adjustable jaws can grip objects of varying sizes. Their locking mechanism ensures that once set, the pressure is consistent, reducing the need for readjustments.

Bar Clamp

The bar clamp comes with a long bar, with one fixed end and another adjustable end. It’s designed to hold wide or long materials together, especially during tasks like gluing.

Though they can be used in woodworking, they find extensive applications in metalworking, especially when working with sheet metals or larger pieces that require uniform pressure across a vast area.

Pipe Clamp

Constructed around a metal pipe, this clamp offers flexibility in terms of length. With two adjustable jaws, one fixed and another sliding along the pipe, users can tailor its size based on the requirement.

Pipe clamps are commonly used in metal fabrication, offering the adaptability to handle large projects or tasks where standard clamp sizes won’t suffice.

Hand Screw Clamp

This clamp, made of two wooden jaws connected by two threaded screws, offers precision in pressure application. Users can adjust each screw independently, allowing for even or uneven pressure based on the task.

Its wooden construction makes it less likely to mar delicate surfaces, and it’s commonly used in tasks where controlled pressure is paramount, excluding furniture-related activities.

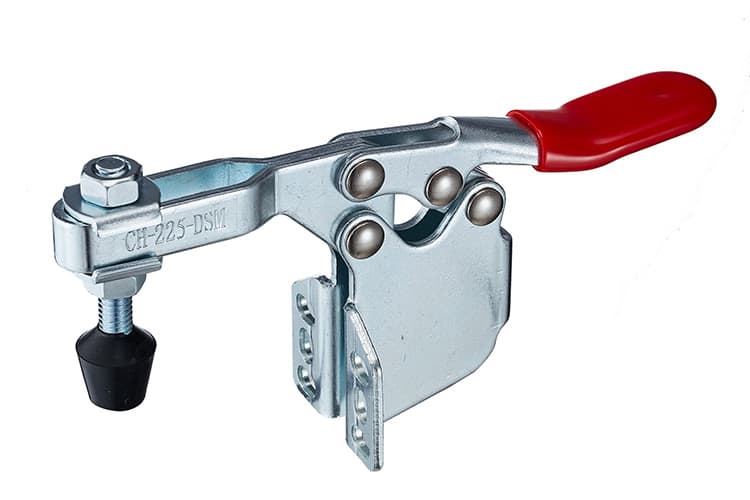

Toggle Clamp

Toggle clamps work on a pivot and lever system. When activated, they lock in place, providing consistent pressure. With a simple mechanism to unlock, they offer quick application and removal.

They’re frequently used in manufacturing setups, where pieces need to be held steadily during machine operations. The consistent pressure ensures that there’s no movement during critical tasks.

Conclusion

Clamps, though often overlooked, are the backbone of many operations. From holding pieces together during welding to ensuring a watertight seal in automotive systems. These tools ensure precision, stability, and safety. Recognizing their varieties and specific uses can make tasks easier and more efficient.

You might also be interested: