In today’s fast-paced world, tools and machinery play a crucial role in ensuring efficiency and precision. Among them, clamps, particularly toggle clamps, have emerged as indispensable assets for a plethora of applications. Grasping their different types and applications can drastically enhance one’s operational efficiency.

Toggle clamps, versatile in design and function, come in several variations tailored for specific tasks. Each type, be it vertical, horizontal, latch-type, push-pull, or pneumatic, has its unique application spectrum in various industries, excluding furniture, architecture, and decoration.

Understanding their distinctions is key to maximizing utility, productivity, and safety in your projects. Dive in to explore the intricacies of each.

What are toggle clamps?

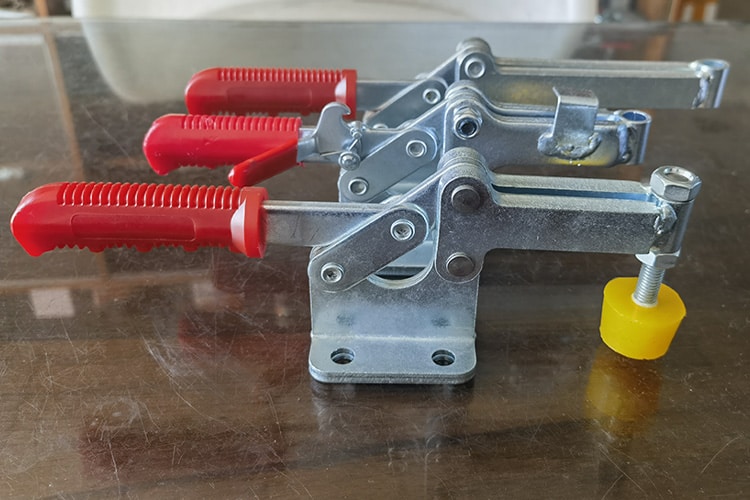

Toggle clamps are mechanical devices that leverage a pivot and lever system to apply pressure and hold a workpiece securely. The primary advantage of these clamps is their ability to apply consistent pressure and a quick-release mechanism, ensuring both stability and efficiency in operations.

These clamps find their importance across industries, especially in environments that require repetitive tasks, as they ensure both speed and precision. Their simple design—lever, pivot, and clamping arm—provides a robust holding mechanism, making them a go-to choice for many.

What are vertical toggle clamps used for?

Vertical toggle clamps, distinguishable by their handle that moves in a vertical direction when locked, are mainly used when the force application needs to be perpendicular to the surface. They have a robust holding capacity and are commonly found in tasks demanding strong downward pressure.

Given their vertical motion, these clamps are perfect for applications where height is restricted, and they can be mounted easily on surfaces, making them highly adaptable to varied setups beyond just furniture or architectural domains.

What are horizontal toggle clamps used for?

Horizontal toggle clamps, as the name suggests, have a handle that moves horizontally when engaged. They are typically employed when there’s a need to exert pressure in a direction parallel to the mounting surface.

Their sideways movement makes them apt for scenarios where vertical space is limited. Industries that involve assembly lines or require clamps that can be seamlessly integrated into broader systems often opt for these clamps due to their compact nature and horizontal clamping action.

What are latch-type toggle clamps used for?

Latch-type toggle clamps operate akin to a door latch. They are equipped with a hook or a latch mechanism, making them adept at joining two bodies together, such as lids to containers or doors to frames.

Because they pull two separate entities into a close, secure connection, they are often used in scenarios that demand quick joining and releasing, all while ensuring that the pieces remain securely connected. Their usability extends to various fields, especially in industries that need rapid yet secure connections.

What are push-pull toggle clamps used for?

Push-pull toggle clamps provide the dual functionality of pushing and pulling, thanks to their design. When the handle is moved, the piston either pushes or pulls the workpiece, depending on its configuration.

Such clamps are ideal for operations that require swift movement between tensioning and compressing actions. They excel in setups that demand both pushing away and pulling in objects, ensuring versatility without compromising the strength of the clamp.

What are pneumatic toggle clamps used for?

Pneumatic toggle clamps are powered by compressed air. The major advantage is the speed and consistent force they can apply, making them apt for automated and semi-automated systems where manual intervention might be minimal.

In industries that prioritize speed, precision, and repeatability—like manufacturing assembly lines or environments with automated machinery—these clamps are invaluable. Their pneumatic nature ensures consistent performance, reducing errors and increasing overall efficiency.

Conclusion

Toggle clamps, in their myriad forms, are pivotal in ensuring efficiency, safety, and precision across multiple industries. Choosing the right type aligns your operations with optimal outcomes, maximizing productivity.

For those in search of premium quality toggle clamps, MAILONG stands as a beacon of excellence. Being a professional manufacturer, we pride ourselves on having all products in stock, ensuring short delivery times. Please feel free to contact us for a quotation.

You might also be interested: