Heavy-duty pneumatic toggle clamps are a type of clamping mechanism that is used in a variety of industries, such as manufacturing, construction, and automotive. These clamps are designed to provide a secure hold on workpieces, allowing for precise and efficient operations. In this article, I will explore six aspects of heavy-duty pneumatic toggle clamps: their construction, operation, applications, advantages, maintenance, and safety considerations.

Construction

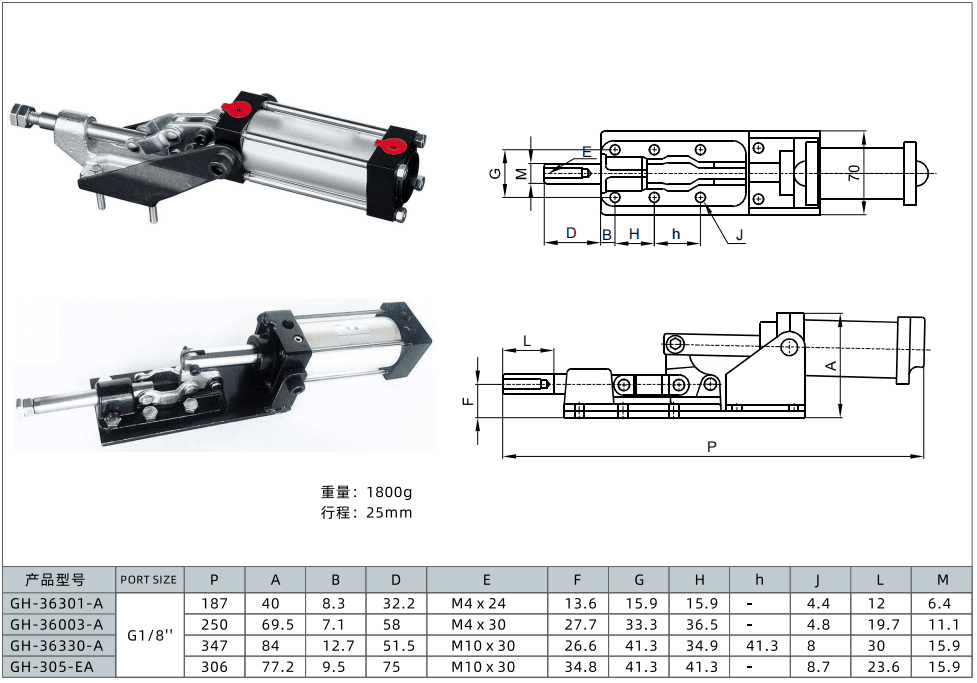

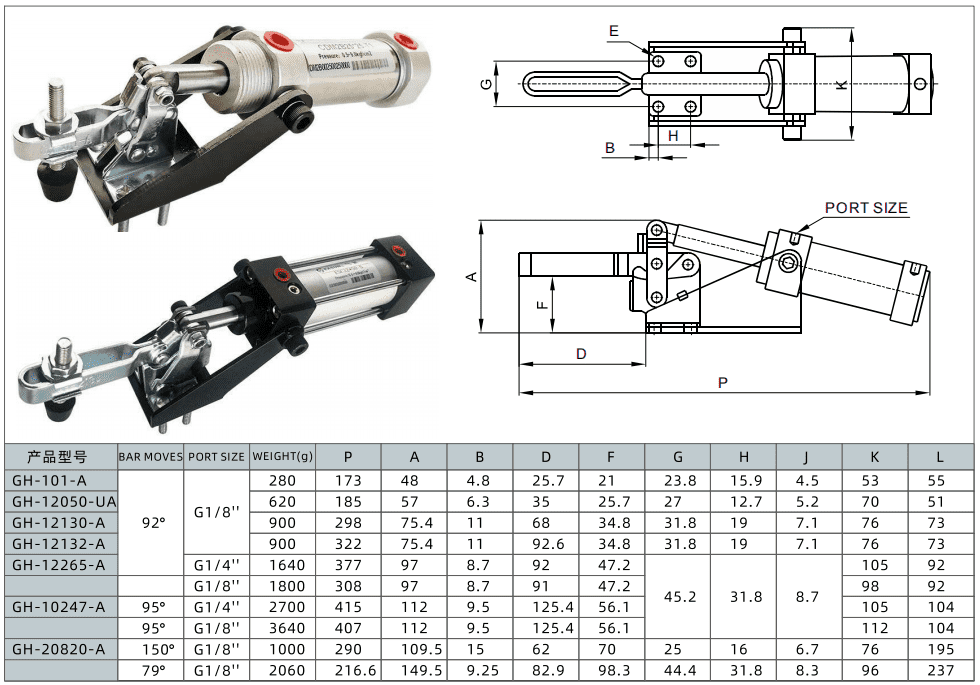

Heavy-duty pneumatic toggle clamps are typically made of high-quality materials such as steel or aluminum. They consist of a base, a lever, and a clamping mechanism. The clamping mechanism is composed of a piston and cylinder, which work together to apply and release pressure on the workpiece. The lever is used to activate the clamping mechanism and secure the workpiece in place.

Operation

Heavy-duty pneumatic toggle clamps are operated using compressed air. The air is fed into the piston, which moves the cylinder and applies pressure to the workpiece. The lever is used to toggle the clamp between the clamping and releasing positions. The toggle mechanism ensures that the clamp stays securely locked in place until the lever is actuated again.

Applications

Heavy-duty pneumatic toggle clamps are used in a wide range of applications, including welding, drilling, milling, machining, and assembly. They are particularly useful in situations where a high degree of clamping force is required, or where repetitive clamping is necessary. They can be used to clamp various shapes and sizes of workpieces, from small parts to large sheets of material.

Advantages

Heavy-duty pneumatic toggle clamps offer several advantages over other types of clamping mechanisms. They provide a high degree of clamping force, which ensures that the workpiece remains securely in place during operations. They also offer quick and easy setups, which makes them ideal for high-volume production environments. Additionally, they are highly durable and can withstand the rigors of heavy use.

Maintenance

Like all tools, heavy-duty pneumatic toggle clamps require regular maintenance to ensure optimal performance and longevity. This includes regular cleaning and lubrication of the moving parts, as well as periodic inspection for wear and damage. It is important to follow the manufacturer’s instructions for maintenance and to replace any worn or damaged parts as soon as possible.

Safety considerations

When working with heavy-duty pneumatic toggle clamps, it is important to follow proper safety protocols to avoid accidents and injuries. This includes wearing appropriate personal protective equipment such as safety glasses and gloves. It is also important to ensure that the clamp is properly secured and that the workpiece is stable before starting any operations. Finally, it is important to follow proper lockout procedures when servicing or repairing the clamp to prevent accidental activation.

In my personal experience, heavy-duty pneumatic toggle clamps are versatile and reliable clamping mechanisms that can be used in a wide range of applications. They offer several advantages over other types of clamps, including a high degree of clamping force, quick and easy setup, and durability. Proper maintenance and safety considerations are essential to ensure optimal performance and prevent accidents and injuries. Are you looking for a custom manufacturer of heavy-duty pneumatic toggle clamps? Then you have come to the right place. Now you can contact us to give you a proposal and the best offer.