Stainless steel vertical toggle clamps are an essential tool for a wide range of industrial applications. They offer a secure and reliable method of holding objects in place, making them ideal for use in woodworking, metalworking, and other industries. In this essay, we will explore five questions related to stainless steel vertical toggle clamps and discuss their benefits, selection, design features, maintenance, and applications.

What are the benefits of using a stainless steel vertical toggle clamp?

Stainless steel vertical toggle clamps are designed to provide a powerful and consistent clamping force, which is essential for many industrial processes. They are made from high-quality materials, such as stainless steel, which makes them resistant to rust and corrosion. This means that they are durable and long-lasting, even in harsh environments.

Another benefit of using stainless steel vertical toggle clamps is their ease of use. They are designed to be simple and intuitive, with a quick-release mechanism that allows for easy adjustment and positioning. This makes them ideal for use in fast-paced industrial settings, where speed and efficiency are critical. You can also go to the special page of Vertical Toggle Clamps to learn more about it.

Furthermore, stainless steel vertical toggle clamps are highly versatile. They can be used to clamp objects of various sizes and shapes, making them suitable for a wide range of applications. They are commonly used in woodworking to hold pieces of wood together while they are being cut or drilled, as well as in metalworking to secure metal parts during fabrication and assembly.

How do you choose the right size and strength for a stainless steel vertical toggle clamp?

When it comes to selecting the right size and strength of a stainless steel vertical toggle clamp for a specific application, there are several factors to consider. The size of the clamp should be chosen based on the size of the object that needs to be clamped, as well as the amount of force required to hold it securely in place. The strength of the clamp is also an important consideration, as it needs to be able to withstand the weight and pressure of the object being clamped. If it is not possible to determine what size quick clamps to use. You can contact us.

What are the key design features of a stainless steel vertical toggle clamp?

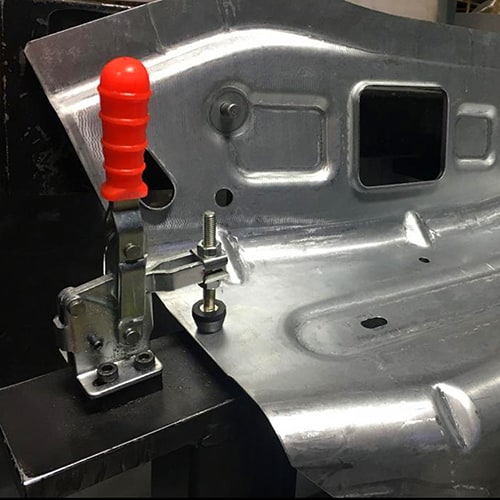

In addition to size and strength, the design features of a stainless steel vertical toggle clamp are also crucial. A well-designed clamp should have a solid and stable base that provides a secure anchor point for the clamp. It should also have a sturdy handle that can be easily operated with one hand, as well as a locking mechanism that holds the clamp firmly in place. You can follow our blog for information on how to use toggle clamps.

Can a stainless steel vertical toggle clamp be used in corrosive environments?

Moreover, the maintenance of a stainless steel vertical toggle clamp is essential to ensure its long-term durability and reliability. The first step in maintaining a clamp is to keep it clean and free from debris, as this can cause it to become clogged or damaged over time. It is also important to lubricate the moving parts of the clamp regularly, as this will help to prevent rust and ensure smooth operation.

What are some common applications for stainless steel vertical toggle clamps?

Finally, what are some common applications for stainless steel vertical toggle clamps in woodworking, metalworking, and other industries? In woodworking, they are used to hold pieces of wood together while they are being cut, drilled, or shaped. They are also commonly used in metalworking to hold metal parts together during fabrication and assembly.

In the automotive industry, stainless steel vertical toggle clamps are used to hold body panels and other components in place during assembly. They are also used in the construction industry to hold large pieces of material together during installation, such as roofing panels or insulation boards.

Overall, stainless steel vertical toggle clamps are an essential tool for many industrial applications. They offer a secure and reliable method of holding objects in place, and their durability, ease of use, and versatility make them an ideal choice for a wide range of industries. By understanding their benefits, selection criteria, design features, maintenance requirements, and applications, you can make an informed decision about which type of stainless steel vertical toggle clamp is best suited for your needs.