In the intricate landscape of industrial manufacturing, precision and efficiency are the game changers. Among the myriad tools available, the humble toggle clamp often raises an intriguing question. With variations aplenty, how does one decide the right fit?

To select the ideal toggle clamp for industrial manufacturing, one must first identify specific requirements, ranging from the type of work to the desired speed and precision. It’s essential to understand the various types of toggle clamps available and their operational mechanics. Safety should be a priority, ensuring the chosen clamp has a reliable locking mechanism and can endure operational pressures. Material durability, adjustability, brand reputation, and after-sales support are other key factors to consider. Always prioritize long-term value over short-term cost savings.

Diving into this article, we’ll unravel the mysteries behind making the right choice, ensuring that your manufacturing processes are both safe and efficient.

Understanding Your Requirement

Before diving into the world of toggle clamps, it’s pivotal to understand your specific requirements. What exactly are you aiming to achieve? Are you looking for speed, precision, or both?

Your application will dictate your choice. For instance, if you’re dealing with heavy-duty objects, a robust clamp becomes indispensable. On the other hand, intricate operations might demand a clamp with a finer grip and precision.

The Types of Toggle Clamps

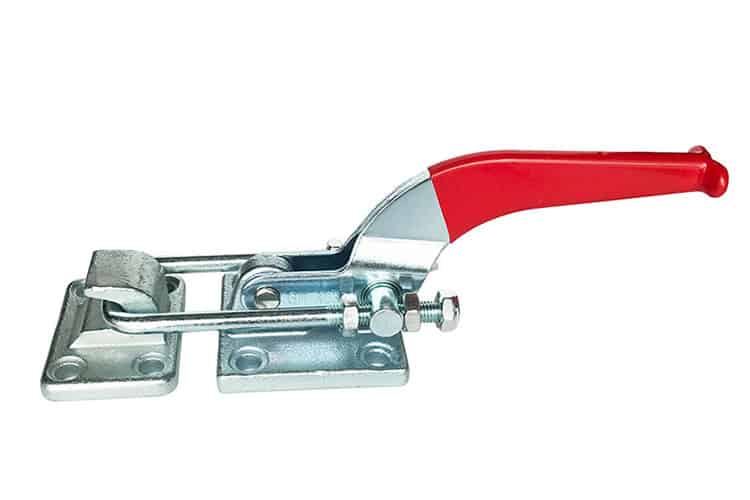

The world of toggle clamps isn’t one-dimensional. You have push-pull clamps, latch clamps, and even horizontal and vertical handle toggle clamps. Each serves a unique purpose.

Understanding each type is essential. Push-pull clamps, as the name suggests, function by pushing or pulling the lever. Latch clamps, on the other hand, are perfect for securing objects together. Familiarize yourself with each variant to make an informed choice.

Operational Mechanics

The operational mechanics of a toggle clamp play a pivotal role in its selection. Does your manufacturing process demand rapid actions? Or does it require a more sustained and consistent clamping force?

Each toggle clamp has its unique mechanics. Being attuned to these can help you choose a clamp that aligns seamlessly with your manufacturing rhythm. Remember, the smoother the integration, the more efficient the process.

Safety First

Safety is paramount, especially in the realm of industrial manufacturing. Your toggle clamp choice should never compromise on safety protocols. Does the clamp have a reliable locking mechanism? Can it withstand the pressures of your operation without faltering?

It’s always wise to opt for a toggle clamp that exceeds your safety expectations. An additional safety margin can often be the difference between a smooth operation and a potential hazard.

Adjustability and Customization

Not all operations are the same. Hence, a one-size-fits-all approach seldom works. The ideal toggle clamp should offer a degree of adjustability.

Whether it’s the clamping force or the grip, having the flexibility to tweak the settings can be a game-changer. Customization ensures that your clamp aligns perfectly with your specific needs, optimizing operational efficiency.

Material and Durability

The material of the toggle clamp isn’t just about aesthetics. It’s closely linked with durability. Whether it’s steel, iron, or even specific alloys, the choice of material can dictate the clamp’s lifespan and resistance to wear and tear.

Investing in a toggle clamp made of high-quality, corrosion-resistant material pays off in the long run. It minimizes frequent replacements and ensures consistent performance.

Price vs. Value

Budget constraints are a reality for many. However, it’s crucial to distinguish between price and value. A cheaper toggle clamp might save you money upfront but could cost more in the long run due to replacements or inefficiencies.

Assessing the value proposition of a toggle clamp, considering its features, durability, and safety, ensures you get the best bang for your buck.

Brand Reputation and Reviews

In the age of digital information, leveraging the experiences of others can be invaluable. Established brands often come with a reputation for reliability and quality.

Going through user reviews, understanding the common issues, and gauging the general sentiment can guide your purchasing decision. It provides insights into real-world performance beyond the glossy advertisements.

After-Sales Support and Warranty

A toggle clamp isn’t a one-off purchase. Over time, it might require adjustments, replacements, or even repairs. How supportive is the brand post-purchase?

Opting for a brand that offers robust after-sales support, easy availability of replacement parts, and a reliable warranty can make your journey much smoother. It’s not just about the product but also the entire experience.

Conclusion

Choosing the right toggle clamp is a blend of understanding, research, and aligning with your specific needs. Prioritizing safety, durability, and efficiency, while being mindful of value, ensures that your manufacturing processes remain seamless and productive. Dive deep, assess your options, and let the toggle clamp be an extension of your manufacturing prowess.

You might also be interested: