In every business, there are critical choices to make, products to assess, and methods to reconsider. At MAILONG, we specialize in the production of toggle clamps, and while I can confidently talk about their numerous benefits, it’s also important to address the potential drawbacks. As the CEO of MAILONG, I believe in offering a transparent overview of our products.

Toggle clamps, like all tools, have their downsides, and it’s essential to weigh these against their benefits before making a purchase decision.

It’s only by acknowledging both sides of the coin can we truly appreciate and understand the real value of a product. So, let’s delve deeper into this topic.

What Makes Toggle Clamps Less Ideal in Certain Situations?

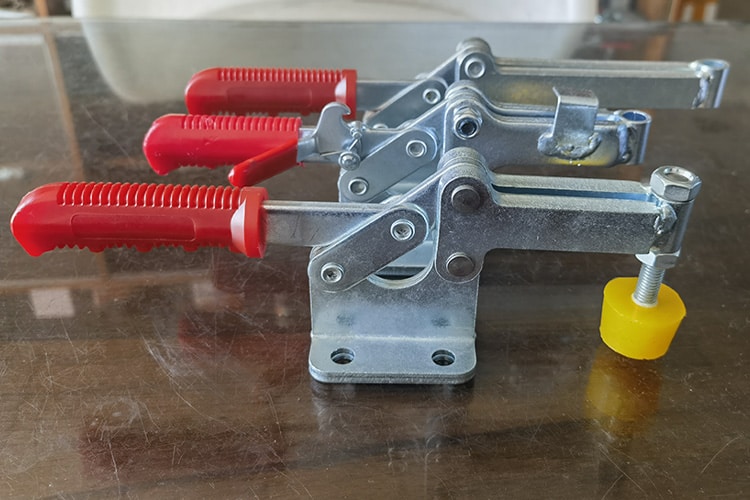

Toggle clamps provide fantastic grip strength and rapid clamping action, but they may not always be the ideal choice for every application. There are some inherent limitations associated with their design and function.

- Limited Clamping Force Range: Toggle clamps are designed for specific force ranges. If the force exerted on the clamp exceeds its design specifications, it could fail.

- Potential for Material Damage: Given their mechanical nature, toggle clamps, especially when not used correctly, could cause damage or deformation to the material they hold, especially if it’s delicate.

- Not Always Ergonomically Designed: Prolonged use of toggle clamps can sometimes cause discomfort to the user, especially if they aren’t designed with ergonomics in mind.

Are There Situations Where Other Clamps Outperform Toggle Clamps?

Absolutely. As a company, while we vouch for the efficiency of our products, we also recognize that there’s no one-size-fits-all in the world of clamping.

- Vibration-Intensive Scenarios: In situations with excessive vibrations, toggle clamps might not maintain their grip as effectively as other specialized clamps.

- High-Temperature Environments: Toggle clamps, depending on the material, might not fare well under extremely high temperatures. Other clamps designed specifically for such scenarios would outperform them.

- Large-scale Projects: For projects that demand the clamping of massive materials or structures, toggle clamps might not be the best choice due to their size and force limitations.

What About Maintenance and Longevity?

No tool is immune to wear and tear, and toggle clamps are no exception. They require regular maintenance to function optimally. Rust, misalignment, and wear on the pivot points can affect their efficiency.

Furthermore, the longevity of a toggle clamp can be compromised if consistently used outside of its intended application or design specs. Proper usage and routine maintenance can, however, significantly prolong their lifespan.

Conclusion

Toggle clamps are incredibly efficient tools, and at MAILONG, we pride ourselves on producing top-quality versions of them. However, understanding their disadvantages is crucial for an informed decision-making process. By being aware of these potential downsides, users can make the most of their toggle clamps and ensure their projects’ success.

You might also be interested: