J hook toggle clamps are an essential tool for industrial clamping applications. Their unique design and structural characteristics make them ideal for a wide range of applications. Including welding, woodworking, and machining. In this article, we will explore the features and uses of j-hook toggle clamps and the benefits they offer over other types of clamps.

What are the j hook toggle clamps?

J hook toggle clamp is a type of clamp used in various industrial applications to hold and secure objects. This clamp is designed to offer quick and easy clamping force by using a simple mechanism that engages and disengages the clamp with minimal effort. The j hook toggle clamp is named for the “J” shape of the hook that secures the object being clamped.

What are the structural characteristics of the j-hook toggle clamps?

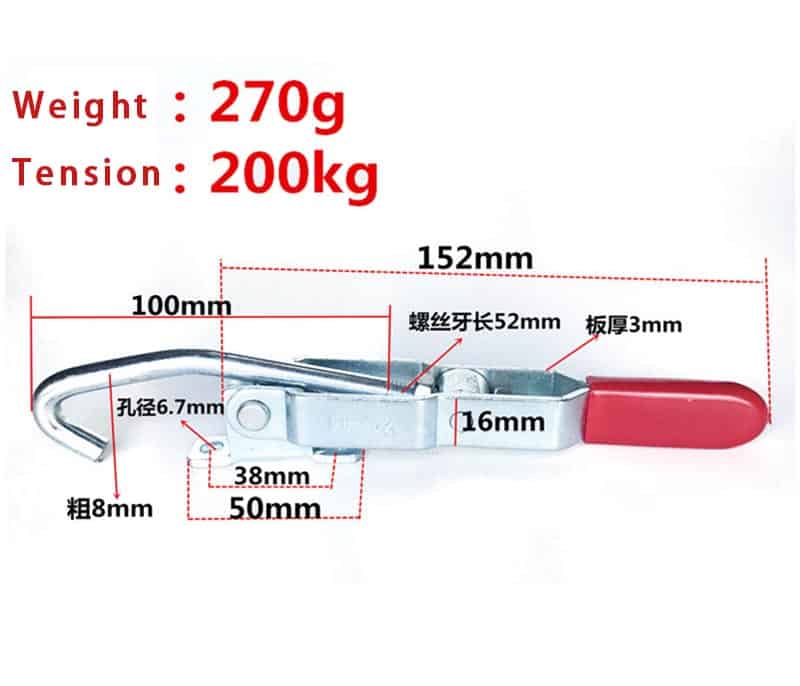

The j hook toggle clamp is a simple device that is made up of a few key components. The clamp consists of a base, a handle, a clamp arm, and a linkage mechanism. And a J-shaped hook. The base of the clamp is typically mounted to a surface or fixture. While the handle is used to engage and disengage the clamp arm. The clamp arm is the component that applies clamping force to the object being held in place. While the linkage mechanism transfers the force from the handle to the clamp arm. The J-shaped hook is used to secure the object being clamped in place. And it can be replaced with other types of hooks or clamping pads to suit specific applications. Its structure is different from our horizontal or vertical quick clamps.

What is the difference between j-hook toggle clamps and ordinary toggle clamps?

The primary difference between j-hook toggle clamps and ordinary toggle clamps is the shape of the hook used to secure the object being clamped. In an ordinary toggle clamp, the hook is typically straight or L-shaped, while the J hook toggle clamp uses a hook that is shaped like a J. This difference in hook shape provides greater versatility and allows for a better grip on a wider range of objects.

What are the uses of the j hook toggle clamp?

J hook toggle clamps are used in various industrial applications where quick and easy clamping force is required. They are particularly useful in applications where the object being clamped is irregularly shaped or difficult to hold with other types of clamps. Some common uses of j-hook toggle clamps include:

Holding workpieces in place during machining or assembly operations

Securing jigs and fixtures to machine tables or workbenches

Clamping materials for welding or brazing operations

Holding components in place during testing or inspection operations

Securing parts during transportation or storage

How to customize the j hook toggle clamp?

J hook toggle clamps can be customized to suit specific applications or to meet the unique requirements of a particular industry. Customization can include changes to the size or shape of the clamp, modifications to the hook or clamping pads. And the use of specialized materials for the construction of the clamp.

Customization may also involve the use of additional features such as a locking mechanism to prevent accidental release of the clamp, or the use of a mounting bracket to allow for easier installation and removal of the clamp.

In my personal experience, j-hook toggle clamps are versatile tools used in various industrial applications. They offer several advantages, including quick and easy clamping force, and versatility. And the ability to clamp a wide range of objects. The primary structural characteristic of the j hook toggle clamp is the J-shaped hook used to secure the object being clamped. Which provides greater versatility compared to other types of clamps. Customization of j-hook toggle clamps can include changes to size and shape, and modifications to the hook or clamping pads. And the use of specialized materials or additional features to meet specific requirements. By selecting the right j hook toggle clamp and customizing it to suit specific applications. Businesses can ensure safe and reliable operations while improving productivity and efficiency.