In the realm of industrial manufacturing, clamping devices play a crucial role in ensuring that workpieces are securely held in place during various processes. Two prevalent types of clamps are the toggle clamp and the RAM clamp. But how exactly do these clamps differ from one another?

Toggle clamps primarily use a lever mechanism to provide a consistent clamping force, while RAM clamps, often found in hydraulic systems, apply force using a cylindrical ram or rod. Both have their distinct advantages and uses within the manufacturing industry.

Understanding the fundamental differences between these two clamps can significantly influence the selection process, ensuring optimal results in specific manufacturing tasks.

How do Their Operating Mechanisms Differ?

The operating mechanisms of the two clamps are starkly different.

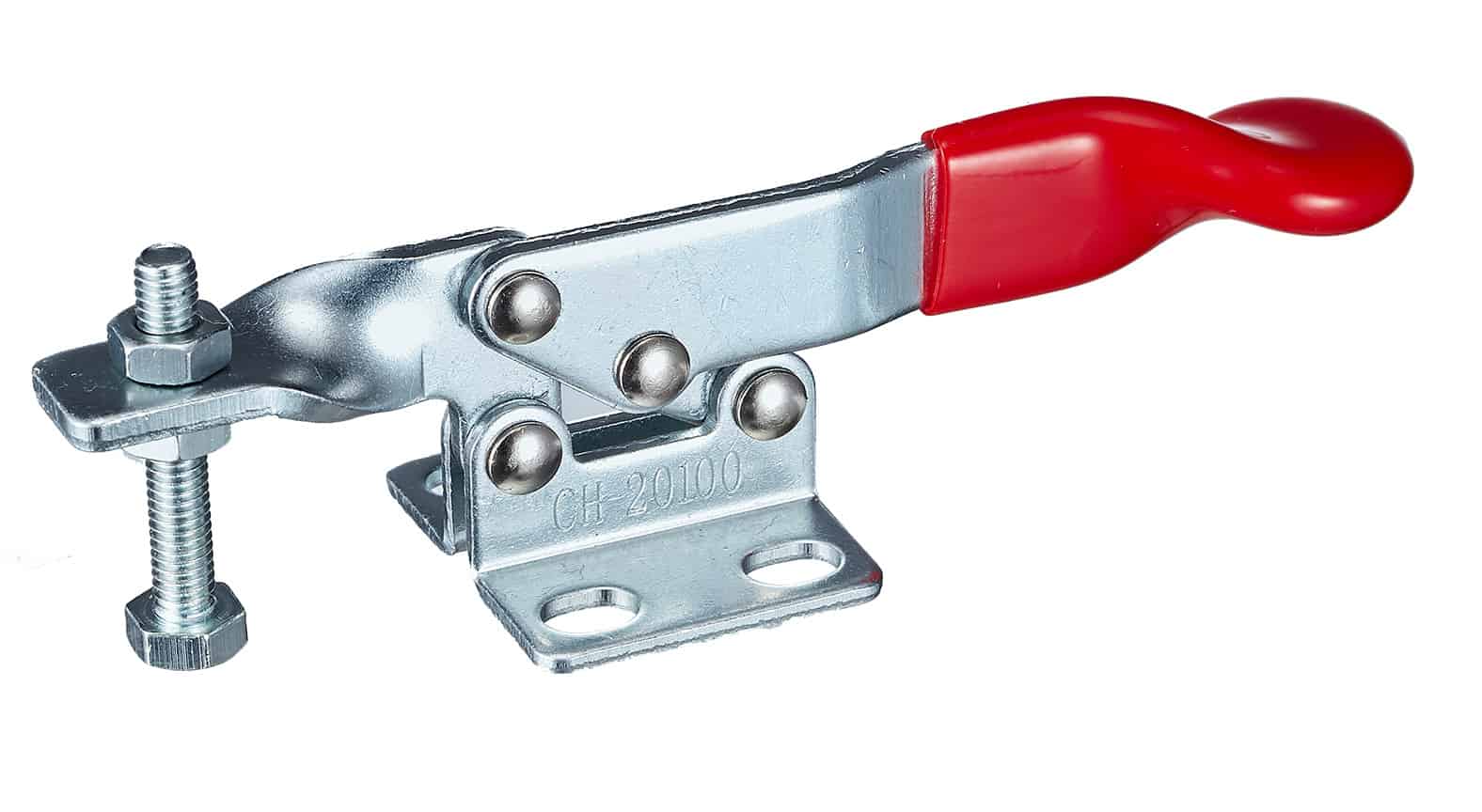

Toggle clamps utilize a lever and pivot system. When the lever is moved, it exerts force on the workpiece, holding it securely in place. This mechanism allows for rapid clamping and releasing, making it suitable for tasks that require frequent adjustments.

RAM clamps, on the other hand, primarily function through a hydraulic or pneumatic system. They use a cylindrical rod or ram that moves vertically to apply clamping force. This method offers a robust and consistent clamping force, ideal for heavy-duty tasks where high pressure is required.

What are Their Material Compositions?

Materials play a vital role in determining the clamp’s durability and suitability.

Toggle clamps are often made of high-strength metals such as steel or stainless steel. These materials offer resilience against wear and tear, ensuring a long lifespan for the clamp. Additionally, the metal construction provides the strength needed for the lever mechanism to function effectively.

RAM clamps, given their usage in hydraulic systems, might be constructed using a mix of metals and durable rubber or plastic components. The metal parts provide the necessary strength, while the rubber or plastic parts ensure the clamp can handle the high pressures associated with hydraulic systems without leakage or failure.

How Do Their Applications Vary in the Industry?

Different manufacturing tasks require different clamping solutions.

Toggle clamps are versatile and find applications in various tasks that require quick clamping and releasing. They are especially useful in situations where workpieces need to be changed frequently, such as in assembly lines or during product inspections.

RAM clamps, with their powerful clamping force, are more suited for heavy-duty tasks. These might include metal forging, stamping, or any other process where substantial and consistent pressure is required to hold the workpiece securely in place.

Which Offers Greater Versatility?

Versatility can be a determining factor for many industries.

Toggle clamps come in various designs, including horizontal, vertical, and push-pull types. This diversity ensures that manufacturers can choose the ideal clamp based on their specific requirements, from holding flat objects to securing items from the side.

RAM clamps, while powerful, might be somewhat limited in terms of versatility. They are typically designed for specific heavy-duty tasks and might not be as adaptable to varied applications as toggle clamps.

How Do Maintenance Needs Compare?

Maintenance ensures longevity and optimal performance.

Toggle clamps, with their simple lever mechanism, require minimal maintenance. Regular checks for wear and tear, combined with occasional lubrication, can ensure they remain in top working condition.

RAM clamps, given their involvement with hydraulic systems, might need more frequent maintenance checks. Ensuring that there are no leaks, checking the hydraulic fluid levels, and inspecting the rubber components are crucial to their effective functioning.

Which is More Economically Feasible?

Cost implications matter in any industrial decision.

Toggle clamps, due to their simplicity, are generally more affordable than RAM clamps. Their metal construction and uncomplicated mechanism make them cost-effective for varied applications.

RAM clamps, while potentially more expensive, offer value in terms of the significant clamping force they provide. For industries that require such robust clamping, the cost might be justified given the efficiency and consistency they bring to the table.

How do Safety Profiles Differ?

Safety is paramount in any industrial setting.

Toggle clamps, with their manual lever mechanism, pose minimal safety risks. Ensuring that they are appropriately locked and releasing them gently can prevent any potential hazards.

RAM clamps, given their association with hydraulic systems, need more caution. Any leaks or malfunctions in the hydraulic system can pose risks. However, when maintained and used correctly, they offer a safe and efficient clamping solution.

How is Set-Up and Ease of Use?

Ease of use can influence productivity.

Toggle clamps, due to their intuitive design, are easy to set up and use. Operators can quickly learn the locking and releasing mechanism, ensuring smooth operations.

RAM clamps might require a more comprehensive set-up, especially if they are part of a larger hydraulic system. However, once set up, they provide a consistent clamping force, requiring minimal adjustments during operations.

Conclusion

While both toggle clamps and RAM clamps serve the primary purpose of securing workpieces, their mechanisms, applications, and advantages vary. Toggle clamps offer versatility and ease of use, making them suitable for a wide range of tasks. In contrast, RAM clamps provide a powerful clamping force, ideal for heavy-duty industrial applications. Understanding these differences can guide manufacturers in choosing the right tool for the job.

You might also be interested: