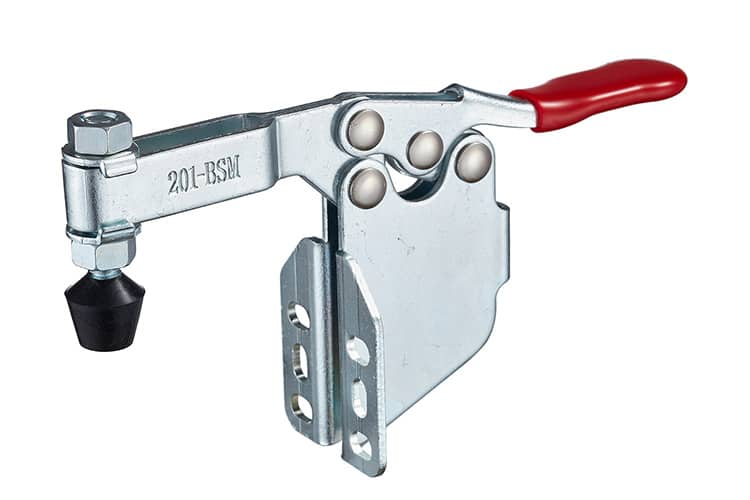

In the bustling world of industrial manufacturing, the tools and equipment used matter immensely. They can influence the efficiency, quality, and safety of the entire process. One of these vital components is the toggle clamp. So, what exactly makes up this essential tool?

Toggle clamps are primarily made of high-strength metals such as steel and stainless steel. They may also feature specific components made of plastic, rubber, or other materials, depending on their design and intended application.

Given the importance and widespread use of toggle clamps in the industrial manufacturing sector, understanding their composition can provide insights into their durability, performance, and application suitability.

Why is Steel Commonly Used in Toggle Clamps?

Steel stands as the go-to material for numerous industrial tools and for good reason.

Steel possesses a high tensile strength, making it highly resistant to external pressures and strains. This resilience ensures that toggle clamps made of steel can withstand significant forces during operations. Its inherent strength ensures a longer lifespan and reduces the chances of wear and tear, thus providing a reliable grip in various applications.

What Benefits Does Stainless Steel Offer?

While steel is robust, stainless steel adds an extra layer of advantage.

Stainless steel, with its resistance to rust and corrosion, ensures that toggle clamps remain unaffected in moisture-prone environments or when exposed to corrosive substances. This resistance extends the clamp’s lifespan, especially in settings like food manufacturing or pharmaceuticals, where hygiene and cleanliness are paramount. Stainless steel toggle clamps thus offer both strength and longevity.

Are There Any Plastic Components in Toggle Clamps?

Beyond metals, plastics also find a place in toggle clamps.

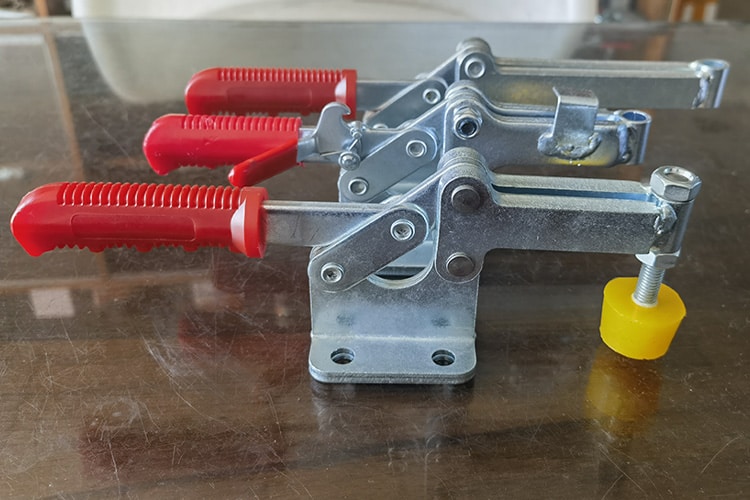

Certain toggle clamps feature plastic components, especially in the handles or grip areas. These plastic parts offer ergonomic advantages, making the clamp more comfortable for operators to handle. Additionally, plastics can resist specific chemicals or solvents that might be present in the industrial environment, thus ensuring the clamp’s integrity.

Why Might Rubber Elements Be Incorporated?

Rubber has unique properties that lend themselves to specific applications.

Some toggle clamps might have rubberized grip areas or pressure pads. Rubber provides a cushioned and non-slip grip, ensuring that the workpiece remains secure without potential damage. Its flexibility also allows for slight adjustments or movements, accommodating workpieces of varied shapes or textures without compromising the clamp’s grip.

How do Alloyed Metals Enhance Toggle Clamps?

Sometimes, it’s not just about pure metals.

Alloyed metals, which are combinations of two or more metals, can bring forth properties that neither metal might offer individually. In the context of toggle clamps, alloyed metals can provide enhanced durability, resistance to specific chemicals, or better thermal stability, making them suitable for specialized industrial applications.

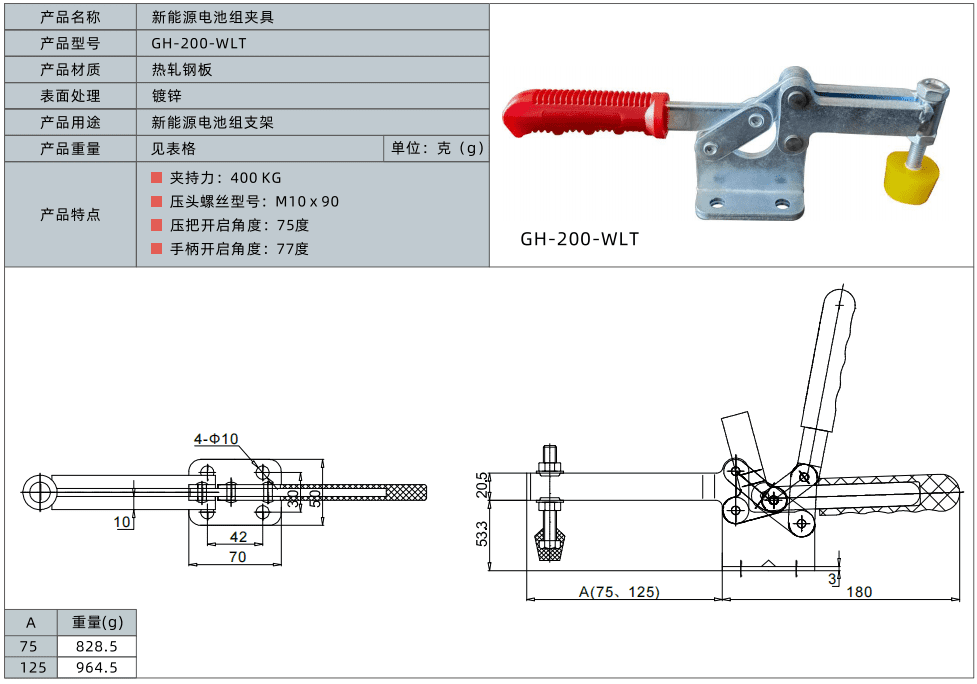

Are There Surface Treatments on Toggle Clamps?

The surface of the clamp matters as much as its core.

Many clamps undergo surface treatments like chrome plating or powder coating. These treatments not only enhance the clamp’s appearance but also provide an added layer of protection against corrosion, wear, or chemical interactions. These coatings can extend the clamp’s lifespan and maintain its performance over time.

What Role do Fasteners Play in Toggle Clamps?

Fasteners, though tiny, play a pivotal role.

The clamps often incorporate fasteners like screws, bolts, or pins made of steel or other durable materials. These fasteners hold the various components of the clamp together, ensuring its stability and function. Given their critical role, these fasteners are typically made of materials that complement the clamp’s overall durability and strength.

Are there Specialized Materials for Specific Industrial Needs?

Industries have varied needs, and the clamps adapt accordingly.

Certain industries might have specialized requirements, be it resistance to high temperatures, specific chemicals, or electrical conductivity. For such specialized applications, the clamps can be made using materials or coatings that cater specifically to these needs, ensuring that the tool remains effective and durable in its intended setting.

Conclusion

Toggle clamps, given their pivotal role in industrial manufacturing, are products of meticulous design and material selection. From steel and stainless steel to plastics and rubber components, every material serves a purpose, ensuring the clamp’s efficiency, durability, and application versatility. By understanding what they’re made of, one can appreciate the intricacies behind these indispensable industrial tools.

You might also be interested: